High-Pressure Lube System Solves Deep-Draw Challenge

March 1, 2012Comments

Specification of an extremely viscous lubricant to deep-draw heavy-gauge compressor shells in a mechanical press created a ripple effect impacting several aspects of the project--the lube-delivery system, transfer-system tooling and the die coating.

This is a story of true cooperation and teamwork among several suppliers, leading to a successful outcome for a uniquely challenging metalforming application. The task: Engineer a process to deep-draw compressor shells in a mechanical press, while avoiding the need for secondary operations. The customer: Bettcher Manufacturing LLC, Reynosa, Mexico, deep-draw specialists serving primarily the HVAC market. The plant operates hydraulic and mechanical presses rated to 900 tons.

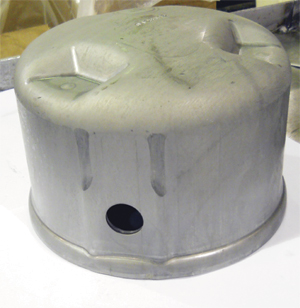

Early in 2011, Bettcher tooling-project engineer Gary James faced the challenge of engineering a process to deep-draw two families of parts for a compressor shell. Upper shells are of 0.155-in.-thick steel with draw height ranging from 6.5 to 8.5 in.; bottom shells are of 0.215-in. steel, with a 7-in. draw height. While Bettcher could easily have formed these parts in any of its hydraulic presses, doing so would have required secondary operations; it sought to run the parts from blank to complete, with holes and forms, in one operation.

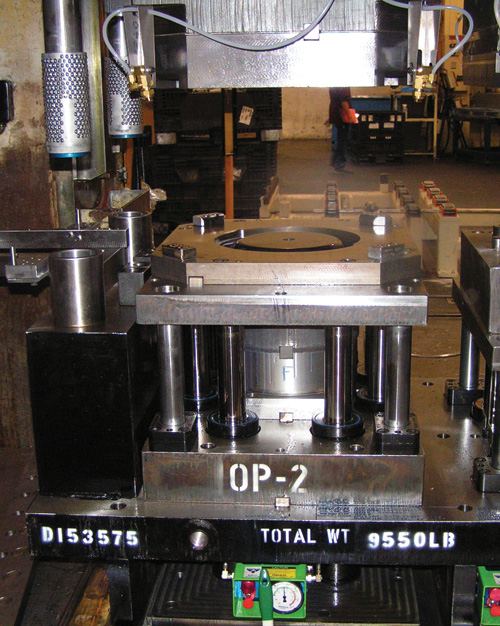

Says James: “We opted to have a transfer die designed and built to run the jobs. And, after reviewing the size of the parts and depth of the draws, we knew the job would take every ounce of capacity from our largest mechanical press, a 900-ton straightside.”

One Heavy-Duty Lube

To run the job in a mechanical press, James and his team also knew that the lubricant and lubricant-application system would hold the keys to the success of the project. And with part volumes of around 1 million per year for one of Bettcher’s primary customers, failure was not an option. The customer had given James and his team six months to move the job from development through to production.

“To run the shells on our big-bed mechanical press (a Bliss 900-ton straightside),” says James, “we knew we had to use the most viscous lube we could find.” The lubricant of choice is a 2000-SUS viscosity heavy oil delivered straight from a 30-gal. reservoir at the press. To provide a system to move the oil from the reservoir to several nozzles stationed in the die, Bettcher turned to Pax Products, which developed a custom lubricant-delivery system built from stock components.

Spraying the lubricant directly inside the die ensures placement of the lube exactly where it’s needed, when it’s needed, says James. And, using the Pax airless-spray system, there’s no concern with atomization and mist. The lube adheres well to the workpiece material and to the tooling, ultimately minimizing lubricant consumption compared to alternative methods.

A Special Die, with a Special Tool Coating

James describes the seven-station transfer die, designed and built for drawing the compressor shells by Walker Tool & Die, Grand Rapids, MI. “We’re drawing in the second and third die stations (the first station is an idle),” says James. “Then we flatten and trim the flange, wipe the flange down and pierce holes in subsequent stations. The two draw stations and flanging stations are most critical, where we absolutely must have dependable, repeatable lubricant application.”