Edge-Rounding Line Prevents Corrosion While Eliminating Labor-Intensive Grinding

December 1, 2015Comments

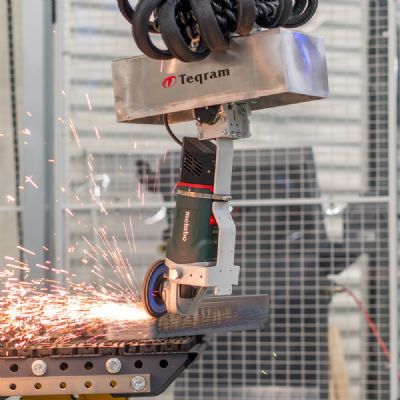

HGG, Charleston, SC, has developed a new edge-rounding line that delivers smooth, rounded surface edges to I- and H-beams, T-bars and flat bars, preventing corrosion while eliminating the labor-intensive costs of grinding. The line is available as a stand-alone machine solution, or it can be fully integrated with an HGG robotic profile-cutting line.

HGG, Charleston, SC, has developed a new edge-rounding line that delivers smooth, rounded surface edges to I- and H-beams, T-bars and flat bars, preventing corrosion while eliminating the labor-intensive costs of grinding. The line is available as a stand-alone machine solution, or it can be fully integrated with an HGG robotic profile-cutting line.

A conveyor provides in-out material feed to the edge-rounding line. Aligning rollers position and guide the material, and an edge-rounding unit stabilizes and rounds the bottom and then top flanges. Says HGG R&D manager Balder de Wolf, “The line can automatically process a radius of 2-3 mm on a beam flange, T-bar and flat bar by rolling the edges. Once the edges are rounded, the beams can easily meet the corrosion-protection requirements.”

www.hgg-group.com

See also: HGG Profiling

Technologies: Finishing