Robotic End-Effector Material-Removal Tool

September 29, 2020Comments

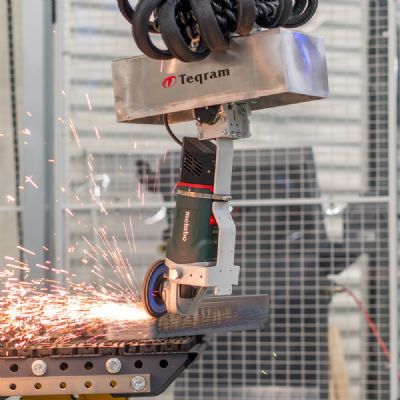

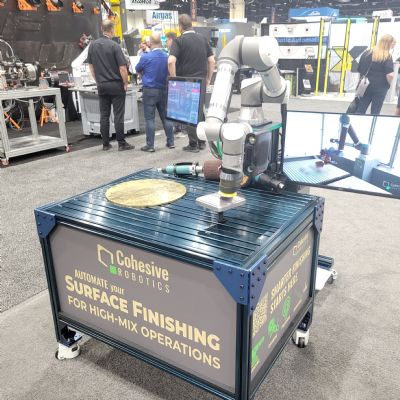

ATI Industrial Automation introduces the RCE-710 radially compliant, electric material-removal tool, the company’s first all-in-one, electrically powered such tool. The RCE-710 features large bearings, a shaft designed for demanding robotic use and a variable-speed motor with a range of 0 to 13,000 rpm. It is built to handle an array of robotic material-removal tasks, such as rust and weld-spatter removal, blending, polishing and light grinding.

ATI Industrial Automation introduces the RCE-710 radially compliant, electric material-removal tool, the company’s first all-in-one, electrically powered such tool. The RCE-710 features large bearings, a shaft designed for demanding robotic use and a variable-speed motor with a range of 0 to 13,000 rpm. It is built to handle an array of robotic material-removal tasks, such as rust and weld-spatter removal, blending, polishing and light grinding.

The new electric tool features built-in compliance to simplify and streamline programming, and to compensate for part and fixturing misalignments. The motor rotates clockwise and counterclockwise, and produces continuous torque on the workpiece.

Available as a complete end-effector package, the RCE-710 includes the deburring tool, power and signal cables and connectors, and a simple-to-use controller. It can perform a variety of tasks with carbide burrs, brushes, flap wheels, unitized wheels, and other cutting, grinding and polishing media.

See also: ATI Industrial Automation

Technologies: Finishing