How Tool Power Affects Abrasive Performance

June 25, 2019 The importance of matching a grinder with the right abrasive product cannot be overstated.

The importance of matching a grinder with the right abrasive product cannot be overstated. Using the right product at the wrong speed, or vice versa, can hinder productivity and may cause unintended effects on the workpiece or abrasives.

|

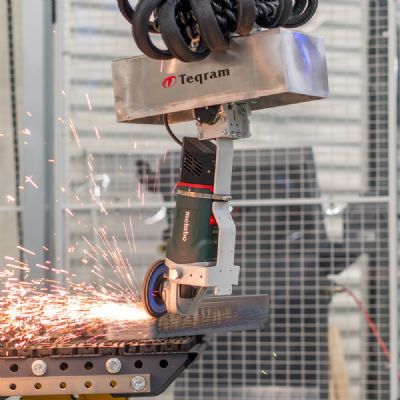

Right-angle grinders, with their wheels turned from the tool at a right angle, are a common tool for cutting, grinding and surface finishing.

|

When choosing a cutting or grinding wheel or flap disc, an operator needs to select one with an RPM rating equal to or higher than that of the tool in use. That is, use larger wheels with lower-RPM tools, and generally smaller wheels with higher-RPM tools.

Over-speeding an abrasive can create a significant safety hazard. Keeping the tool guard on at all times not only protects the operator, but also prevents using larger wheels or flaps discs on a tool not rated for them.

Additionally, operators must ensure that the arbor holes on the wheels precisely match their mandrels. Without that, the product could spin out-of-round, creating another safety issue. Also necessary: the need to ensure that the product sits properly, or else risk damaging the arbor and causing a wheel to break apart. In addition, incorrect mounting may significantly shorten the life of an abrasive.

The Main Tools for the Job

Common tools for cutting, grinding and surface finishing include an electric or pneumatic right-angle grinder with which cutting wheels, flap discs and grinding wheels frequently are used.

Another: die grinders for small spaces and with smaller-diameter products or products with stems attached. Die grinders can be electric, though most are pneumatic. When the setup cannot accommodate the footprint of a right-angle or die grinder, there’s the inline grinder. With this option, the wheel is perpendicular to the straight end of the tool, unlike a right-angle-grinder wheel, which is located to a right angle from the tool itself.

Factors Affecting Tool Power

Several factors affect tool power, performance and safety:

- Amperage. A tool’s amperage keeps the motor spinning consistently at the same speed. When a tool has low amps and an operator applies pressure on the abrasive, the tool will not sustain consistent RPM. With higher-amperage tools, operators maintain power without overheating the motor, increasing motor life and abrasive effectiveness.

- Grains. The abrasive’s grains also affect tool power. For example, an operator would need a higher-amperage tool to maximize the efficiency of the grains on a ceramic cutting or grinding wheel. The wheel would need to spin at higher RPMs to fracture the ceramic grains and enable self-sharpening and continual high performance. If a low-amperage tool isn’t getting the job done with a ceramic or zirconia-alumina wheel, an aluminum-oxide wheel requiring less torque may be better. It often makes more sense, economically, to replace the abrasive rather than upgrade the tool.

- Cutting/grinding angle. An increased angle increases the material removal rate when grinding, but it also can cause the operator to put more pressure onto the abrasive itself. More pressure adds more heat and the possibility of the tool bogging down.

- Extension cord quality. Using an inexpensive or low-quality extension cord affects tool power. For example, a heavy-duty, 12-gauge extension cord allows for grinding with full RPMs while being farther from the power source than a common store-bought 16-gauge cord. Also, a thinner extension cord may allow the tool to run at free speed and at its rated RPM, but it will likely stall out once the operator adds any kind of load to it.

- Air-compressor quality. Operators should consider how their air compressors rate when compared to the number of export air hoses needed when using pneumatic die grinders. If there are multiple cells using air tools, multiple air compressors or higher quality compressors may be required to feed those cells. The cell farthest away from the air compressor may have the lowest air pressure.