Exchangeable-Head Milling System with Internal Coolant

July 1, 2013Comments

Sandvik Coromant, Fair Lawn, NJ, introduces the CoroMill 316 exchangeable-head milling system with internal coolant delivery, ideal for high-feed face milling, slot milling, helical interpolation, shoulder milling, profile milling and chamfer milling of components in material groups from ISO P to ISO S. Machining these heat-resistant superalloys, titanium alloys and stainless steels often requires the use of coolant for temperature control and chip evacuation during cutting. Recutting of chips and chip jamming often lead to poor surface quality, damage to the cutting edge and tool breakage.

By offering an internal coolant solution, with precise positioning of coolant holes to optimize the effect of the coolant jet, CoroMill 316 reportedly will outperform existing solutions using external coolant.

CoroMill 316 end mills are even suitable for five axis milling of flanks, which often require tapered tools for stability at longer tool reach.

Sandvik Coromant: 800/726-3845; www.sandvikcoromant.com

See also: Sandvik Coromant Company

Technologies: Finishing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Finishing

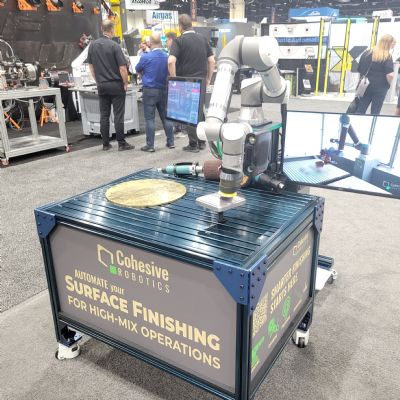

FinishingAutomated Finishing Cell for High-Mix Applications

Wednesday, November 20, 2024

Finishing

FinishingArku Sets Up Shop in South Carolina

Tuesday, September 17, 2024