Carbide Burrs for Surface Removal in Demanding Applications

January 1, 2018Comments

Norton | Saint-Gobain Abrasives, Worcester, MA, has released a new line of carbide burrs designed for surface removal during demanding production runs. Double-cut carbide burrs are ideal for quickly removing surface stock, weld splatter, deburring and chamfering applications, along with medium to light cleaning.

The specially designed geometries of these burrs result from growing demands for stainless steel, mild steel, cast steel and composites applications, and offer rapid stock removal and long product life. The carbide burrs can be used on hand-held tools such as Norton’s die grinder or automated CNC machines. The Norton carbide-burr line encompasses 30 different parts and is offered in seven types including; SA cylindrical without end cut; SB cylindrical with end cut; SC ball-nosed cylindrical; SD ball shape; SF ball-nosed tree; SG tree with taper; and SL ball-nosed cone. A kit containing the most popular five burr types, for smaller job requirements, is available.

Norton | Saint-Gobain Abrasives: www.nortonabrasives.comView Glossary of Metalforming Terms

See also: Saint Gobain Abrasives, Norton Abrasives

Technologies: Finishing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Finishing

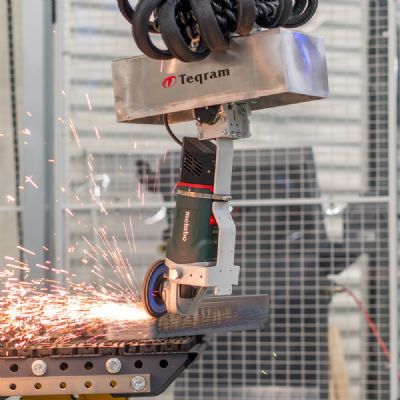

FinishingVia 3D Vision, Robotic Grinding Without Programming

Monday, March 3, 2025

Finishing

FinishingArku Sets Up Shop in South Carolina

Tuesday, September 17, 2024

Finishing

FinishingUpgraded High-Performance Cutting, Grinding and Combination ...

Wednesday, August 28, 2024