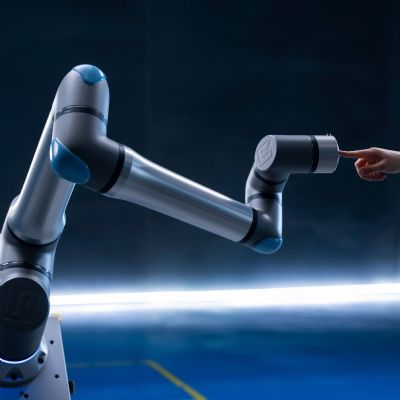

Standard industrial robots can operate near workers as long as appropriate safety and sensing hardware is used. These robots typically represent the best choice when personnel only need to access a workcell infrequently—perhaps only every few hours to reload raw materials or check critical part features. Cobots, on the other hand, prove ideal for working alongside humans to assist with dull, dirty and dangerous jobs while a nearby operator typically performs tasks that require manual skills.

Gone are the days of needing huge conveyors and fixed guarding that occupy large chunks of floor space. In most cases, today’s robots can locate parts from any orientation—with the help of 2D or 3D robot vision, for example. Vision systems enable robots to pick randomly oriented parts from bins, totes or any types of containers. Upon picking, a robot can reorient the part as needed, and quickly load it to a workholding device. When that portion of the operation completes, the robot transfers the part to the next task, enabling production to proceed at needed speeds without bottlenecks.

Another flexible robot solution designed to help manufacturers deal with capacity shortfalls and labor shortages: mounting a robot to a mobile platform. Such platforms enable movement of robots to different machines on the plant floor, and quick setup for any number of tasks.

Possible in Low-Volume, High-Mix Operations

Even though today’s robots and cobots improve throughput, increase flexibility to tackle multiple operations and reduce operating costs, a wide gap still exists between manually tended machines and those automated with robots. Lights-out manufacturing remains a far-reaching goal for some metal formers and fabricators. Typical lights-out operations employ robots for large-batch/high-volume runs at night, without the need for human intervention, while smaller-batch lower-volume jobs run during the day with more staff available. However, a growing number of robotic solutions prove capable of handling low-volume, high-mix jobs typically found in smaller operations and job shops. Here, a robot handles different-sized parts in a family or group of parts, allowing for rapid changeover when the parts change. This technology continues to improve.

Robotic machine tending has revolutionized manufacturing in other ways, too, allowing manufacturers to increase overall equipment effectiveness. Once the robot loads a machine, it can perform secondary processes such as deburring, cleaning, inspection and much more utilizing the same gripper or a quick tool changer if needed. And, we’ve seen more cases where manufacturers produce their own specialized grippers and other end-of-arm tools for various applications (often with a big assist from additive manufacturing), thus adding bang to the robot buck.

Robotic machine tending has revolutionized manufacturing in other ways, too, allowing manufacturers to increase overall equipment effectiveness. Once the robot loads a machine, it can perform secondary processes such as deburring, cleaning, inspection and much more utilizing the same gripper or a quick tool changer if needed. And, we’ve seen more cases where manufacturers produce their own specialized grippers and other end-of-arm tools for various applications (often with a big assist from additive manufacturing), thus adding bang to the robot buck.

Determining ROI Quantitatively and Qualitatively

The financial metrics for robotics and automation have improved significantly over the years as robots and other automation devices have become smarter, more flexible and reliable. However, manufacturers new to automation and considering robots for the first time benefit from taking a tactical approach to ROI. Develop an automation strategy based on the competitive advantages that automation can bring to your organization.

Typically, ROI presentations are transaction-based, covering metrics and measures focused solely on the ability to reduce costs. A new transformative-based approach to determining the ROI for robots and automation includes evaluating key benefits and opportunities such as:

- Enhanced process quality and reliability

- Better use of skilled workers, increased morale and employee engagement

- Improved insights from data collection

- Creation of a genuine transformative experience for the entire company.

The combination of qualitative measures with financial estimates makes it easier for corporate management to approve an investment in automation. Why? As the automation market evolves, manufacturing executives have come to realize that the quantifiable cost savings achieved through automation represent just the beginning of investment potential.

Automated systems not only help manufacturers increase capacity and meet customer demands, they enhance the careers of the current workforce. Especially in today’s tight labor market, companies that invest in workforce development increase the likelihood that skilled employees will advance in their careers inhouse and be more likely to stay.

Cost Savings

Many companies begin an automation project intending to reduce costs and increase savings by minimizing the time employees spend on dull, dangerous and dirty tasks. These savings arise in the form of improved efficiencies, higher throughput, reduced risk of injuries and less absenteeism due to fatigue or boredom. Manufacturers investing in automation and robotics can achieve much higher efficiency rates, and at the same time create a better work environment that inspires employees to be more productive.

Common Solutions

Manufacturers with similar processes at multiple locations should look to common automation approaches for achieving a higher ROI. Once the individual pilot system completes and operates successfully, it’s then standardized to achieve a broader-scale solution. In simplistic terms, this copy-and-paste concept allows a manufacturer to employ the same automation solution in other areas that perform the same or similar processes. Doing so provides an impressive benefit for large or complex organizations, enabling realization of exponential automation ROI. In addition, common solutions ease upskilling of the workforce, reduce spare-parts inventories and speed deployment as compared to customized systems.

Improved Quality and Employee Satisfaction

Well-designed, fully programmed automated systems typically do not make mistakes. A robot performing a specific task presents no risk of human error. Moving the operator to the skilled position of managing the robotic workcell rather than performing the task helps improve quality, consistency and reliability.

In addition, the jobs employees enjoy least generally include those most suitable for automation. As mentioned, employees relieved from performing undesirable tasks can focus on more rewarding jobs that require human skills. Robotic automation truly transforms the jobs of employees who can shift from transferring, handling or packing products to managing the robots and other automation that perform these tasks.

Enhanced Process Insights

As part of Industry 4.0, a key advantage today is the ability to monitor and record the jobs performed by an automated system. Process audits of the data collected from a robot or other automation equipment are key drivers toward transformational change. Companies with access to critical data make continuous improvements, reduce costs and stay competitive.

Develop a Center of Excellence

Implementing a well-designed method to manage a manufacturer’s automation systems provides significant benefits and helps reduce risks. How? The leading approach today: creating an automation center of excellence (CoE) that becomes a guide for the manufacturer’s automation journey. The CoE uses data to help build a common structure and process for all automation projects, from selecting the right automation partner to how the system is designed and deployed. The CoE also can manage identification of a new automation project and ensure a quality and structured process. All of this results in standardized and defined processes that include built-in control checks to help improve compliance, demonstrate capability and produce documentation to support a variety of uses.

In the end, demonstrating how automation will help reduce costs certainly appeals to a manufacturer’s decision makers. However, showing how automation can drive value and enable true transformational change will deliver the funding and support you need. MF

Information provided by Fanuc America Corp., Rochester Hills, MI; 888/FANUC-US; www.fanucamerica.com.

View Glossary of Metalforming Terms

See also: FANUC America, Inc.

Technologies: Pressroom Automation

As a result and as the numbers show, robots and cobots have infiltrated manufacturing environments. For the third-straight quarter, robot sales in North America hit a record high, according to 2022 2Q report from the Association for Advancing Automation.

As a result and as the numbers show, robots and cobots have infiltrated manufacturing environments. For the third-straight quarter, robot sales in North America hit a record high, according to 2022 2Q report from the Association for Advancing Automation.