“We explore the use of steel in automotive markets to provide a better understanding of the markets and how megatrends and evolving regulations impact steel applications,” says Coates, offering an overview and noting that research and engineering occurs for programs such as Steel E-Motive through acclaimed organizations and universities worldwide to ensure that research remains objective. “We generate data for our stakeholders worldwide and work toward demonstrating the value of, and opportunities for, steel solutions in automotive markets. Driving up the strength of materials such as AHSS requires the exploration of how to form and fabricate these materials—presses, tooling, surface treatments, etc. So, we work closely with automakers, steelmakers and organizations such as the AISI’s Auto/Steel Partnership on these issues.”

Focuses on Mobility as a Service

|

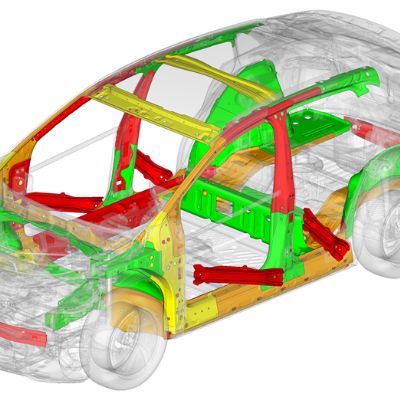

WorldAutoSteel’s Steel E-Motive program explores the autonomous, battery electric vehicles (BEVs) that may inhabit our world within the next couple decades, with a focus on how advanced high-strength steels can play a large role in their safe, affordable performance. Beyond their look, design and manufacture, such vehicles will incorporate a dizzying array of tech. These BEVs, produced for Mobility as a Service providers and targeting a ride-sharing and hailing population, “will connect to roads as well as infrastructure,” offers George Coates, technical director of WorldAutoSteel and project manager for Steel E-Motive. “In smart cities, these vehicles will communicate with traffic signals, roadside lighting, buildings, infrastructure and other vehicles. All of this technology must incorporate seamlessly and without fail.” While such sensor technology goes beyond the marching orders of Steel E-Motive, the program nonetheless, according to Coates, employs partner research organizations to provide insight on the technology, and how it can be incorporated into BEV designs. |

WorldAutoSteel and Steel E-Motive in particular looks at the ramifications of new mobility and the idea of MaaS based on previous WorldAutoSteel research.

“Think of the megacities with all of the pollution and congestion, where people don’t want to own cars,” Coates offers, commenting on the trend toward MaaS. “There may be an enormous fee just to get access, or to title a vehicle. Some Chinese cities, for example, require fees of more than $100,000 just for the right to own a vehicle. And parking fees in major cities may far exceed the monthly lease cost of a vehicle. We're seeing major trends in megacities where people are dismissing automotive ownership, preferring instead to hail or share rides. Areas without good public-transportation infrastructure also see this trend.

“As a result,” he continues, “World-AutoSteel explores the impact of such a shift in mobility on our markets. Following from that, and more importantly to us, what happens when you completely design and build an electrified, autonomous vehicle from ground up?”

WorldAutoSteel’s Steel E-Motive program focuses on the following future-vehicle specifications to guide its research, with such vehicles being:

Indeed, the considerations are many. Full autonomy may result in no need for a steering wheel and pedals, for example, and offers new degrees of design freedom.

“What can we do from a steel perspective?” asks Coates. “How can we leverage steel in new designs while still meeting all of the safety challenges and regulations? Our research has told us that we need a program that really addresses MaaS, which represents a radical departure from conventional vehicle architectures.”

Thus, the WorldAutoSteel Steel E-Motive program was born.

As described on the program’s website: “Steel E-Motive’s objective is to demonstrate that AHSS products and technologies can solve the unique architectural challenges of MaaS, ultimately providing virtual concepts as roadmaps for affordable, safe, mass and environmentally efficient vehicles. Ride-hailing, autonomous electric-vehicle fleets will deliver transportation to millions around the world. With a vast portfolio of AHSS and steel technologies from which to draw, we envision that Steel E-Motive will deliver innovative ideas for steel vehicle architectures that will shape the future of sustainable mobility.”

Battery-Case Opportunities Abound

The battery compartment, essential in the BEV equation, represents a major Steel E-Motive study area.

“A battery case presents big opportunities for steel, including design of the case as part of the vehicle structure,” Coates offers. “Tied into the rockers, the case becomes integral to overall body-structure stiffness and part of the crash solution. Depending on the design and how the case integrates with the rockers, it helps for side-impact crash and crush, and helps manage load paths at the front and rear ends of the vehicle.”

Additionally, according to Coates, BEVs must meet three key battery-case safety requirements:

- No leakage from the battery pack during a crash event

- No intrusion into the passenger compartment

- No thermal runaway that creates a fire or explosion.

“Typically, the bottom of a battery case will be designed and built to prevent road debris from damaging the battery pack and causing electrolyte leakage or a spill that can lead to a thermal event,” Coates explains. “Also, a cover between the battery case and the floor of the vehicle prevents anything from entering the passenger compartment and affecting the occupants. These are perfect applications for AHSS.”

While BEVs have hit the marketplace, with many more coming, no battery-case standards exist for materials.

“Cases are made with all types of material, and with material mixes,” says Coates. “We’re working on some solutions that we think will be quite unique and affordable because they’re made out of steel.”

More Interior Room Challenges Safety Needs

A completely autonomous ride-hailing vehicle, as mentioned, may forego pedals, steering wheels and more, presenting other opportunities for steel.

“Designers can cannibalize what used to be a lot of this front-end structure, using it instead for occupant space and maybe even for packaging of luggage and other goods for transport,” Coates says. “Such vehicles still must meet crash requirements, and as front and rear ends are shortened, these vehicles offer less structure to deal with a crash. We see demand here for very-high-strength materials, and the new steel grades play well into such applications.”

Offering another application potential for steel: ingress and egress.

“Picture a megacity, where a vehicle will pull to a curb to let riders in and out,” Coates posits. “Ingress and egress become big issues. We have to figure out how to do that—the kinds of closures to use, for example. The most efficient way to get people in and out might be to remove the B pillar, but doing this creates issues with side loads and crash management. So, we’re exploring solutions that may be available only from steel due to its excellent attributes.”

Affordable and Green are Musts

Environmental performance, of course, is part and parcel of any BEV discussion. Here, steel brings advantages, too, according to Coates.

“Steel is the most recycled and most efficiently converted material on earth,” he says. “We want to leverage steel’s environmental advantages along with the strength, weight and design advantages to make vehicles that meet all the functional needs, while offering environmental efficiency and affordability.”

Such affordability is the key to making all of this work.

“Think of the mobility service provider that seeks a profitable business case,” Coates says. “This provider wants to make money selling these services. It wants safe vehicles, which consumers demand, along with reliable and comfortable vehicles.

“Reliability and durability play into the total cost of ownership,” he continues, “as well as into the actual cost of a vehicle. The use of materials in a vehicle and the selected fabrication processes drive the cost. Should the materials be steel, WorldAutoSteel believes that mobility service providers end up with the most affordable solution. Steel E-Mobility is evaluating all of these things.”

Prepare by Beefing Up for AHSS

For metal formers looking to benefit from the BEV revolution, Coates offers that efforts made to tackle AHSS-forming issues today provide an excellent blueprint.

“We're talking about new materials and new fabrication processes to produce these future BEVs,” he says. “We’re continuing to drive up both the strength and the formability of steels through the third-generation-steel development program, as well as through the use of press-hardened, or hot-forming steels. A lot of this work falls to the Tier One and Tier Two suppliers. These suppliers will want to continue innovating, and adopting new manufacturing capabilities that allow them to produce components, architectures and subsystems out of AHSS and hot-formed steels. We’ll want efficient, lightweight vehicles—and they are made possible through the use of these materials.

“Expect a greater need for high-performance machines such as servo-driven presses and robust material feed lines,” Coates concludes, “along with better tooling materials, better surface treatments, new welding and joining technologies, etc.” MF

See also: Worldautosteel

Technologies: Materials

“Steel E-Motive follows a long history of steel-industry collaboration and commitment to support the evolution of vehicle design and use,” said Cees ten Broek, WorldAutoSteel director, in announcing the program. “With a vast portfolio of advanced high-strength steels (AHSS) and steel technologies from which to draw, we envision that Steel E-Motive will deliver new, exciting ideas for steel vehicle architectures that will shape the future of sustainable mobility.”

“Steel E-Motive follows a long history of steel-industry collaboration and commitment to support the evolution of vehicle design and use,” said Cees ten Broek, WorldAutoSteel director, in announcing the program. “With a vast portfolio of advanced high-strength steels (AHSS) and steel technologies from which to draw, we envision that Steel E-Motive will deliver new, exciting ideas for steel vehicle architectures that will shape the future of sustainable mobility.”