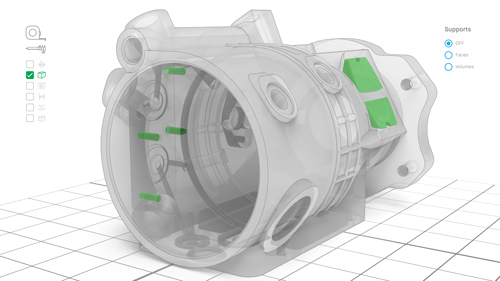

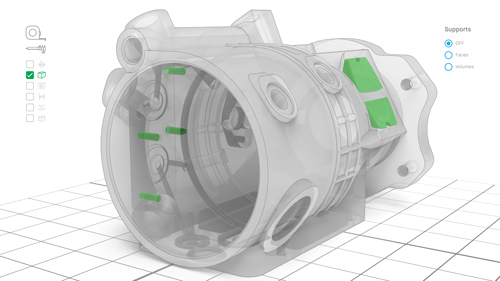

Flow print-preparation software includes support generation when needed, process selection, slicing and simulation of complex part designs to validate execution feasibility before the build. Geometrical feature-driven processing enables low angles below 5 deg. In addition, deformation correction technology enables the user to produce parts without the need for iterations, achieving a first-print success rate to 90 percent, according to Velo3D officials.

Following RAPID + TCT, Velo3D announced that it has partnered with Boom Supersonic, a Colorado-based firm now building what company officials say will be the world’s fastest supersonic airliner, the XB-1 Mach-2.2 (1687 mph) demonstrator aircraft, designed for speed to Mach 2.2, or 1687 mph.

Boom and Velo3D have conducted successful validation trials with plans calling for the installation of two 3D printed titanium parts on the prototype aircraft in early 2020 as part of a control for ensuring safe flight in all conditions.

www.velo3d.com

Intricate Electronics via Inkjet Deposition

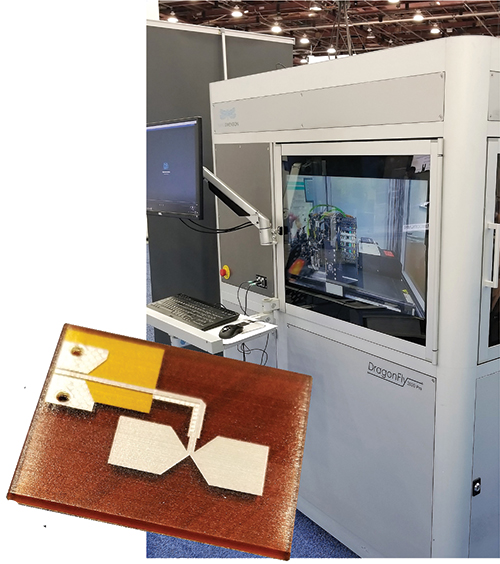

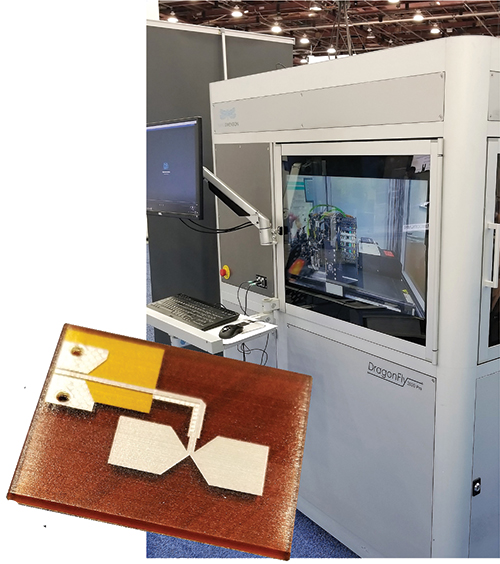

On display by Nano Dimension: the DragonFly Pro 3D printer, offered as a one-stop solution for 3D printed electronics. The printer, currently employed by R&D teams, enables users to move quickly from concept verification and design validation to test fixtures via 3D printing their own professional circuit boards, according to company officials. This provides the ability to keep sensitive and proprietary design information inhouse while developing.

On display by Nano Dimension: the DragonFly Pro 3D printer, offered as a one-stop solution for 3D printed electronics. The printer, currently employed by R&D teams, enables users to move quickly from concept verification and design validation to test fixtures via 3D printing their own professional circuit boards, according to company officials. This provides the ability to keep sensitive and proprietary design information inhouse while developing.

The printer features a precise inkjet deposition system for high-resolution ‘trace-and-space,’ enabling construction of a full range of multi-layer PCB features including interconnections such as buried vias and plated through-holes. Users reportedly enjoy the rapid production of professional multi-layer PCB prototypes, antennas, experimental electronic circuits and more.

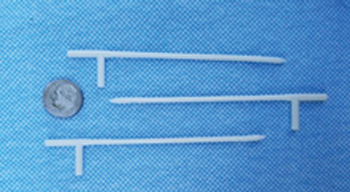

The booth included a number of intricate samples on display, including a 3.7 by 0.4-in. ultra-wide-band antenna (pictured), showing the printer’s ability to print RF antennas. Time to print: 12 hr. for four units.

Just prior to RAPID + TCT, Nano Dimension announced that it had created, on the DragonFly, the first fully functional, 3D printed communication device, reportedly at a faster speed than has been achieved to date with traditionally made devices. Nano Dimension completed the print, assembly and testing of the company-developed prototype IoT transceiver device (smaller than a silver-dollar coin) in approximately 18 hr., approximately 90-percent faster than non-3D printed, which can take 14 days or more.

www.nano-di.com

New Version of AM Simulation Suite Speeds Design Time, Reduces Waste

Fresh off of RAPID + TCT, AlphaStar Corp. has released Version 9 of its additive manufacturing (AM) simulation suite Genoa 3DP. The suite uses multi-scale progressive failure analysis to simulate the AM process from material characterization to process simulation and in-service qualification of a printed part.

Genoa 3DP v9, as described by AlphaStar officials, accurately predicts deformation, residual stress and damage initiation, and also determines voids, warpage and other manufacturing anomalies seen in 3D printing. Additionally, Genoa 3DP allows end users to assess material and process-parameter sensitivities, thus significantly reducing trial and error, material waste and engineering time.

This particular release reportedly improves user-friendliness, enhances coupling with commercial finite element analysis (FEA) solvers and introduces the addition of two new modules: PathCoverage and TMg. A print-path-error management tool, PathCoverage visualizes and accounts for problematic regions of printed parts. TMg, a thermal-management tool, quickly and accurately predicts thermal history, material states, and dynamic evolution of melt-pool and heat affected zones, according to AlphaStar officials, while identifying stable and unstable zones during the print process.

Additional new features in Genoa 3DP v9 include metal as well as polymer AM support, support of external mesh from FEA software, design of experiment via the Surrogate Modeling Optimization tool, and prediction and incorporation of temperature-dependent 3D printed material properties. To ease use, the software includes more than 30 step-by-step tutorials.

www.alphastarcorp.com

NanoParticle Jetting Successes Pave Way for Metal Applications

XJet announced the sale and installation of two Carmel 1400 NanoParticle Jetting (NPJ) systems to the University of Delaware, where researchers employ 3D ceramic printing to develop cutting-edge antenna technology for 5G network applications, and to Marvel Medtech, a medical-device startup that 3D prints ceramic cryotherapy probes for a robotic intervention guidance system. The system freezes and destroys tiny breast-cancer tumors. For use in MRI scans, not x-rays, the system represents a break from traditional mammograms. XJet’s vice president of healthcare, Avi Cohen, told 3DMP that he expects that the company’s success with ceramic applications will soon lead to metal 3D printed medical applications, such as controlled-release, drug-delivery systems and stents.

XJet announced the sale and installation of two Carmel 1400 NanoParticle Jetting (NPJ) systems to the University of Delaware, where researchers employ 3D ceramic printing to develop cutting-edge antenna technology for 5G network applications, and to Marvel Medtech, a medical-device startup that 3D prints ceramic cryotherapy probes for a robotic intervention guidance system. The system freezes and destroys tiny breast-cancer tumors. For use in MRI scans, not x-rays, the system represents a break from traditional mammograms. XJet’s vice president of healthcare, Avi Cohen, told 3DMP that he expects that the company’s success with ceramic applications will soon lead to metal 3D printed medical applications, such as controlled-release, drug-delivery systems and stents.

www.xjet3d.com

Ordering and Workflow Management System for Prototypes

Fab Flow, a customizable tool from Desktop Metal, enables managers to improve operations across the shop floor, identifying underutilized machines and spotting backlogs before they build up. Shops also can provide internal customers with a simple ordering interface reflecting the shop’s equipment, technologies and processes. This allows for accurate price quoting, automated printability analysis and delivery estimates for ordered parts. Design engineers also can communicate, iterate and track the progress of their parts in real-time.

Fab Flow, a customizable tool from Desktop Metal, enables managers to improve operations across the shop floor, identifying underutilized machines and spotting backlogs before they build up. Shops also can provide internal customers with a simple ordering interface reflecting the shop’s equipment, technologies and processes. This allows for accurate price quoting, automated printability analysis and delivery estimates for ordered parts. Design engineers also can communicate, iterate and track the progress of their parts in real-time.

Key features of Fab Flow include:

- Customizable shop configuration and ordering interface

- Instant and comprehensive price quoting

- Live job tracking and updates

- Automated printability analysis

- Interactive 3D model viewer for designers

- Contextualized design communication.

www.desktopmetal.com

3D Printed Milling Tool, New Ni-Based Superalloys and AM Diamond Composite

Sandvik had a host of innovations on display, including the AM version of its CoroMill 390 milling cutter. 3D printing resulted in an optimized design, 80-percent lower weight and as much as 200-percent increased productivity when using the tool, according to company officials. Topology optimization resulted in the weight savings, with the tool material changed to a titanium alloy and produced via powder bed laser fusion. Reducing weight at the end of the milling assembly significantly reduces vibration in the system, thus smoothing cutting performance and leading to the stated productivity increase.

Sandvik had a host of innovations on display, including the AM version of its CoroMill 390 milling cutter. 3D printing resulted in an optimized design, 80-percent lower weight and as much as 200-percent increased productivity when using the tool, according to company officials. Topology optimization resulted in the weight savings, with the tool material changed to a titanium alloy and produced via powder bed laser fusion. Reducing weight at the end of the milling assembly significantly reduces vibration in the system, thus smoothing cutting performance and leading to the stated productivity increase.

Also, the company revealed at RAPID + TCT that it has added nickel-based superalloys to its Osprey metal-powder roster. The superalloys, produced in Sandvik’s atomizing plant, reportedly are ideal for AM applications.

In addition, Sandvik touted development of a proprietary process to 3D print diamond composite via stereolithography, enabling the hard material to be printed in highly complex shapes without the need for further machining. Included was a sample of a 3D printed diamond composite. Most of the material is diamond, but to make it printable and dense, according to Sandvik officials, it must be cemented in a very hard matrix material, keeping the most important physical properties of pure diamond.

“On seeing its potential, we began to wonder what else would be possible from 3D printing complex shapes in a material that is three times stiffer than steel, with heat conductivity higher than copper, the thermal expansion close to Invar—and with a density close to aluminum,” says Anders Ohlsson, delivery manager at Sandvik Additive Manufacturing. “These benefits make us believe that you will see this diamond composite in new advanced industrial applications ranging from wear parts to space programs, in just a few years from now.”

www.additive.sandvik/en

Automated Metrology-Grade Desktop 3D Scanner

Artec Micro’s Artec 3D, an automated, metrology-grade desktop 3D scanner, comes equipped with cutting-edge twin cameras. LED lights, synchronized with the scanner’s dual-axis rotation system, enable digital copies using minimal frames and point accuracy to 10 microns, a tenth the size of a single grain of table salt. Intuitive and simple-to-use, the scanner requires minimal training, according to company officials. After placing an object on the circular scanning platform, the operator chooses from a variety of smart scanning paths and clicks to begin. The scanning process can be viewed in real-time within Artec Studio.

Artec Micro’s Artec 3D, an automated, metrology-grade desktop 3D scanner, comes equipped with cutting-edge twin cameras. LED lights, synchronized with the scanner’s dual-axis rotation system, enable digital copies using minimal frames and point accuracy to 10 microns, a tenth the size of a single grain of table salt. Intuitive and simple-to-use, the scanner requires minimal training, according to company officials. After placing an object on the circular scanning platform, the operator chooses from a variety of smart scanning paths and clicks to begin. The scanning process can be viewed in real-time within Artec Studio.

www.artec3d.com

New Materials for EOS Printers

EOS displayed a variety of parts and AM machines, and highlighted its continued development of materials to serve the industry. This includes the introduction of four metal materials specifically developed for AM: EOS StainlessSteel CX, EOS Aluminium AlF357, EOS Titanium Ti64 Grade 5 and EOS Titanium Ti64 Grade 23. They have been tailored to suit an array of applications, ranging from automotive to medical.

EOS displayed a variety of parts and AM machines, and highlighted its continued development of materials to serve the industry. This includes the introduction of four metal materials specifically developed for AM: EOS StainlessSteel CX, EOS Aluminium AlF357, EOS Titanium Ti64 Grade 5 and EOS Titanium Ti64 Grade 23. They have been tailored to suit an array of applications, ranging from automotive to medical.

The company offers comprehensive data for all four metals, including the number of test specimens on which the mechanical properties are based, as well as detailed scanning-electron-microscope images that provide insight into material quality. This provides companies with documentation and transparency that make it easier for them to compare direct metal laser sintering (DMLS) 3D printing with traditional manufacturing and other 3D printing technologies, according to EOS officials, who note that such data and openness are requirements for the use of AM in series production.

EOS StainlessSteel CX, a new tooling-grade steel developed for production with the EOS M 290 machine, combines corrosion resistance with high strength and hardness. Components made from this material reportedly are simple to machine and provide an excellent polished finish.

EOS Aluminum AlF357, ideal for applications requiring a light metal with mechanical/thermal strength, deliver components characterized by light weight, corrosion resistance and high dynamic loading. This material has been developed for production with the EOS M 400, but EOS plans to make it available for the EOS M 290 system in the near future.

EOS Titanium Ti64 Grade 5, specially developed for its high fatigue strength without hot isostatic pressing (HIP), is suitable for production with the EOS M 290. The material also offers excellent corrosion resistance, making it ideal for aerospace and automotive applications, according to company officials.

EOS Titanium Ti64 Grade 23 also was developed for its high fatigue strength without HIP and for production with the EOS M 290. Compared to Ti64, this material reportedly offers improved elongation and fracture toughness with slightly lower strength, making it well-suited to medical applications.

EOS classifies the technological maturity of all its polymers, metals and processes in the form of Technology Readiness Levels (TRLs). The TRL concept, developed by NASA, is established in numerous industries. For simplified orientation, the company divides its materials and processes into two categories: TRL 3-6 refer to core products, while TRL 7-9 denote premium products and address the usage for series applications. The new materials belong to the following categories:

- EOS StainlessSteel CX—TRL 8

- EOS Aluminium AlF357—TRL 7

- EOS Titanium Ti64 Grade 5—TRL 7

- EOS Titanium Ti64 Grade 23—TRL 7.

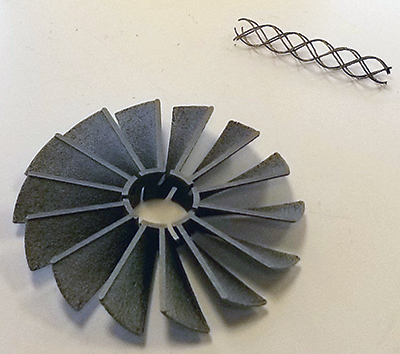

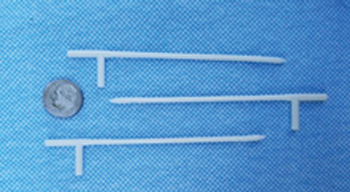

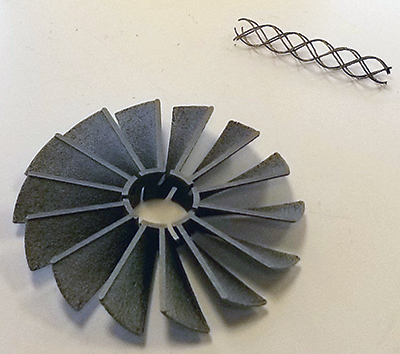

The company also showcased its development of shape-memory materials for aerospace and medical applications, including a nickel-titanium alloy (pictured).

www.eos.info/en

Robotic Integration for AM, Plus Bulk Alloy Development

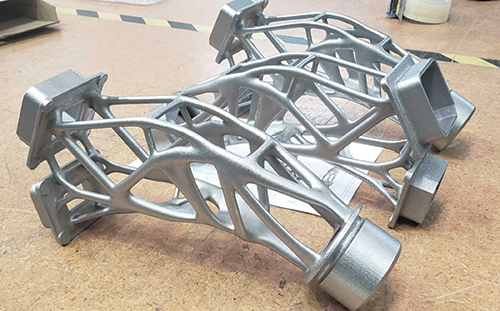

A developer and provider of directed energy deposition systems and related products, Formalloy used the show to demonstrate robotic integration for metal AM.

A developer and provider of directed energy deposition systems and related products, Formalloy used the show to demonstrate robotic integration for metal AM.

Its X series boasts improved quality, better powder efficiency, and the ability to print with the most comprehensive list of metal alloys on the market, according to company officials. Each series machine includes the Formalloy AX metal deposition head and a customizable build volume with as many as five axes of motion. The Formalloy AX head reportedly has proven reliable for as much as 8 kW of laser power and includes built-in quick-release features that allow for rapid maintenance and component swaps in less than 3 min. As an alternative to purchasing a turnkey metal deposition system, a robot can be integrated with the Formalloy AX head, Formalloy ADF or PF powder feeders, and laser to 3D print, clad and repair metal parts.

The new ADF (Alloy Development Feeder), also demonstrated at RAPID + TCT, enables high-throughput bulk alloy synthesis for development of new materials and alloys. By innovating in the alloy development space, Formalloy is enabling not only researchers but also end users by enabling rapid development of new alloys that can be utilized for product improvement and enhanced material properties for their own product, according to company officials.

Besides new-alloy development, the ADF enables precise deposition of gradient materials. Each layer is pre-alloyed to ensure composition accuracy for detailed gradient strategies not achievable with other processes. Gradient parts can offer enhanced material properties and simplification of multiple-part assemblies made of various metals into a single part.

www.formalloy.com

Deposition Printers Installed Globally

Spee3D, the Melbourne, Australia-based firm with reportedly the first-ever metal 3D printer using supersonic 3D deposition technology to deliver manufacturing-grade printing at production speeds, has announced the installation of printers at Swinburne University in Melbourne, Australia; Fit AG in Lupburg, Germany; and at the University of Delaware in the United States.

Spee3D, the Melbourne, Australia-based firm with reportedly the first-ever metal 3D printer using supersonic 3D deposition technology to deliver manufacturing-grade printing at production speeds, has announced the installation of printers at Swinburne University in Melbourne, Australia; Fit AG in Lupburg, Germany; and at the University of Delaware in the United States.

At RAPID + TCT this past May, the company showcased its LightSpee3d and large-format WarpSpee3d printers. Rather than using heat to melt metal powders, these machines employ supersonic deposition, where a nozzle accelerates air to as much as three times the speed of sound to deposit injected powders onto a substrate attached to a six-axis robotic arm. The kinetic energy of the particles, explain company officials, causes the powders to bind together to form a high-density part with normal metallurgical properties.

www.spee3D.com

Product Development via Computational Engineering

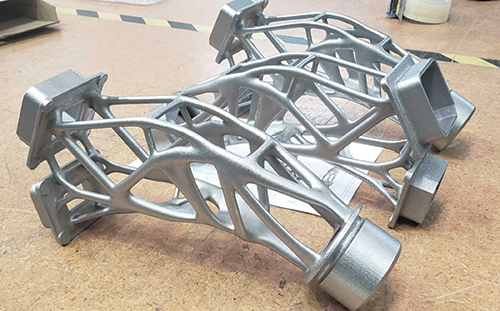

nTopology’s computational-engineering approach to creating complex designs relies on implicit modeling using a unified, purely algorithm-based environment for processing geometry, simulation, and manufacturing rules and outputs through a single, highly automated platform. Design teams can overlay complementary information into a single engineering model, enabling rapid design iterations and leading to increased product functionality, mass customization, one-off designs and localized manufacturing.

nTopology’s computational-engineering approach to creating complex designs relies on implicit modeling using a unified, purely algorithm-based environment for processing geometry, simulation, and manufacturing rules and outputs through a single, highly automated platform. Design teams can overlay complementary information into a single engineering model, enabling rapid design iterations and leading to increased product functionality, mass customization, one-off designs and localized manufacturing.

www.ntopology.com

Gauging System for Large Parts

Building on the success of its Equator 300 gauging system, Renishaw introduced its Equator 500 for larger parts, with a working volume to 20 in. dia. and to 16 in. tall. Both the 300 and 500 stay accurate between 41 F and 122 F at any rate of temperature change, and are capable of scanning speeds in excess of 8 in./sec. The base of the Equator 500 supports workpiece and fixturing with a total weight limit of 221 lb. The ratio of gauging volume to footprint means that the machine is space efficient—with a footprint of 36.2 in. by 36.4 in., the 500 fits alongside production machines. Typical applications include car and truck transmission and engine casings, drive-train parts, suspension castings, pressed parts, valves, and pumps.

Building on the success of its Equator 300 gauging system, Renishaw introduced its Equator 500 for larger parts, with a working volume to 20 in. dia. and to 16 in. tall. Both the 300 and 500 stay accurate between 41 F and 122 F at any rate of temperature change, and are capable of scanning speeds in excess of 8 in./sec. The base of the Equator 500 supports workpiece and fixturing with a total weight limit of 221 lb. The ratio of gauging volume to footprint means that the machine is space efficient—with a footprint of 36.2 in. by 36.4 in., the 500 fits alongside production machines. Typical applications include car and truck transmission and engine casings, drive-train parts, suspension castings, pressed parts, valves, and pumps.

www.renishaw.com/equator500

Design and Engineering Software with Powerful Sim. Capabilities

Altair Engineering showcased its design and engineering software, including comprehensive simulation capabilities. These are consolidated in the newly released HyperWorks 2019, a comprehensive open-architecture simulation platform that, as the company demonstrated at RAPID + TCT, unifies design, engineering and manufacturing communities for faster development cycles.

The 2019 version of this simulation- and AI-driven product-development platform expands on the number of solutions available for designers and engineers to speed decision-making and time to market, including user-experience advancements and intuitive workflows.

Highlights include expanded nonlinear solver functionality through Altair OptiStruct, ideal for users performing stiffness, strength and fatigue-life simulations. The single-model, multi-attribute workflow enabled by OptiStruct enables design decisions to be made quickly by engineers performing linear, nonlinear, and durability analysis—using one optimization-ready model.

HyperWorks 2019 also includes SimSolid for rapid simulation of complex assemblies; HyperLife for simple-to-learn fatigue-life prediction; SimLab, an intuitive workflow platform for simulating multiphysics problems; and HyperMesh for generation of large, complex finite element models.

In addition, Altair Inspire, included in the HyperWorks platform, provides a generative design/topology-optimization and rapid simulation solution for design engineers. It enhances the concept development process, according to company officials, by enabling simulation-driven design to increase a product’s efficiency, strength and manufacturability, leading to reduced costs, development time, material consumption and product weight.

www.altair.com/HW2019 3DMP

Industry-Related Terms: Alloys,

Bed,

Conductivity,

Core,

Corrosion Resistance,

Dimension,

Form,

LASER,

Layer,

Manufacturability,

Mesh,

Model,

Prototype,

SubstrateView Glossary of Metalforming Terms

See also: Renishaw Inc., Altair Engineering, Inc., Sandvik Coromant Company, EOS of North America, Inc., Desktop Metal, Inc.

Technologies:

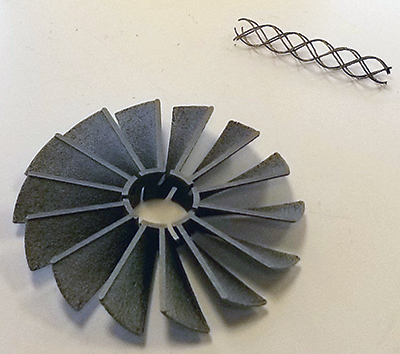

Velo3D had on display an impressive array of parts produced via its Sapphire 3D print system and Flow print-preparation software, with Intelligent Fusion technology optimizing the process by combining thermal process simulation, print prediction and closed-loop control during print execution.

Velo3D had on display an impressive array of parts produced via its Sapphire 3D print system and Flow print-preparation software, with Intelligent Fusion technology optimizing the process by combining thermal process simulation, print prediction and closed-loop control during print execution.

On display by Nano Dimension: the DragonFly Pro 3D printer, offered as a one-stop solution for 3D printed electronics. The printer, currently employed by R&D teams, enables users to move quickly from concept verification and design validation to test fixtures via 3D printing their own professional circuit boards, according to company officials. This provides the ability to keep sensitive and proprietary design information inhouse while developing.

On display by Nano Dimension: the DragonFly Pro 3D printer, offered as a one-stop solution for 3D printed electronics. The printer, currently employed by R&D teams, enables users to move quickly from concept verification and design validation to test fixtures via 3D printing their own professional circuit boards, according to company officials. This provides the ability to keep sensitive and proprietary design information inhouse while developing. XJet announced the sale and installation of two Carmel 1400 NanoParticle Jetting (NPJ) systems to the University of Delaware, where researchers employ 3D ceramic printing to develop cutting-edge antenna technology for 5G network applications, and to Marvel Medtech, a medical-device startup that 3D prints ceramic cryotherapy probes for a robotic intervention guidance system. The system freezes and destroys tiny breast-cancer tumors. For use in MRI scans, not x-rays, the system represents a break from traditional mammograms. XJet’s vice president of healthcare, Avi Cohen, told 3DMP that he expects that the company’s success with ceramic applications will soon lead to metal 3D printed medical applications, such as controlled-release, drug-delivery systems and stents.

XJet announced the sale and installation of two Carmel 1400 NanoParticle Jetting (NPJ) systems to the University of Delaware, where researchers employ 3D ceramic printing to develop cutting-edge antenna technology for 5G network applications, and to Marvel Medtech, a medical-device startup that 3D prints ceramic cryotherapy probes for a robotic intervention guidance system. The system freezes and destroys tiny breast-cancer tumors. For use in MRI scans, not x-rays, the system represents a break from traditional mammograms. XJet’s vice president of healthcare, Avi Cohen, told 3DMP that he expects that the company’s success with ceramic applications will soon lead to metal 3D printed medical applications, such as controlled-release, drug-delivery systems and stents. Fab Flow, a customizable tool from Desktop Metal, enables managers to improve operations across the shop floor, identifying underutilized machines and spotting backlogs before they build up. Shops also can provide internal customers with a simple ordering interface reflecting the shop’s equipment, technologies and processes. This allows for accurate price quoting, automated printability analysis and delivery estimates for ordered parts. Design engineers also can communicate, iterate and track the progress of their parts in real-time.

Fab Flow, a customizable tool from Desktop Metal, enables managers to improve operations across the shop floor, identifying underutilized machines and spotting backlogs before they build up. Shops also can provide internal customers with a simple ordering interface reflecting the shop’s equipment, technologies and processes. This allows for accurate price quoting, automated printability analysis and delivery estimates for ordered parts. Design engineers also can communicate, iterate and track the progress of their parts in real-time. Sandvik had a host of innovations on display, including the AM version of its CoroMill 390 milling cutter. 3D printing resulted in an optimized design, 80-percent lower weight and as much as 200-percent increased productivity when using the tool, according to company officials. Topology optimization resulted in the weight savings, with the tool material changed to a titanium alloy and produced via powder bed laser fusion. Reducing weight at the end of the milling assembly significantly reduces vibration in the system, thus smoothing cutting performance and leading to the stated productivity increase.

Sandvik had a host of innovations on display, including the AM version of its CoroMill 390 milling cutter. 3D printing resulted in an optimized design, 80-percent lower weight and as much as 200-percent increased productivity when using the tool, according to company officials. Topology optimization resulted in the weight savings, with the tool material changed to a titanium alloy and produced via powder bed laser fusion. Reducing weight at the end of the milling assembly significantly reduces vibration in the system, thus smoothing cutting performance and leading to the stated productivity increase. Artec Micro’s Artec 3D, an automated, metrology-grade desktop 3D scanner, comes equipped with cutting-edge twin cameras. LED lights, synchronized with the scanner’s dual-axis rotation system, enable digital copies using minimal frames and point accuracy to 10 microns, a tenth the size of a single grain of table salt. Intuitive and simple-to-use, the scanner requires minimal training, according to company officials. After placing an object on the circular scanning platform, the operator chooses from a variety of smart scanning paths and clicks to begin. The scanning process can be viewed in real-time within Artec Studio.

Artec Micro’s Artec 3D, an automated, metrology-grade desktop 3D scanner, comes equipped with cutting-edge twin cameras. LED lights, synchronized with the scanner’s dual-axis rotation system, enable digital copies using minimal frames and point accuracy to 10 microns, a tenth the size of a single grain of table salt. Intuitive and simple-to-use, the scanner requires minimal training, according to company officials. After placing an object on the circular scanning platform, the operator chooses from a variety of smart scanning paths and clicks to begin. The scanning process can be viewed in real-time within Artec Studio.  EOS displayed a variety of parts and AM machines, and highlighted its continued development of materials to serve the industry. This includes the introduction of four metal materials specifically developed for AM: EOS StainlessSteel CX, EOS Aluminium AlF357, EOS Titanium Ti64 Grade 5 and EOS Titanium Ti64 Grade 23. They have been tailored to suit an array of applications, ranging from automotive to medical.

EOS displayed a variety of parts and AM machines, and highlighted its continued development of materials to serve the industry. This includes the introduction of four metal materials specifically developed for AM: EOS StainlessSteel CX, EOS Aluminium AlF357, EOS Titanium Ti64 Grade 5 and EOS Titanium Ti64 Grade 23. They have been tailored to suit an array of applications, ranging from automotive to medical. A developer and provider of directed energy deposition systems and related products, Formalloy used the show to demonstrate robotic integration for metal AM.

A developer and provider of directed energy deposition systems and related products, Formalloy used the show to demonstrate robotic integration for metal AM. nTopology’s computational-engineering approach to creating complex designs relies on implicit modeling using a unified, purely algorithm-based environment for processing geometry, simulation, and manufacturing rules and outputs through a single, highly automated platform. Design teams can overlay complementary information into a single engineering model, enabling rapid design iterations and leading to increased product functionality, mass customization, one-off designs and localized manufacturing.

nTopology’s computational-engineering approach to creating complex designs relies on implicit modeling using a unified, purely algorithm-based environment for processing geometry, simulation, and manufacturing rules and outputs through a single, highly automated platform. Design teams can overlay complementary information into a single engineering model, enabling rapid design iterations and leading to increased product functionality, mass customization, one-off designs and localized manufacturing.  Building on the success of its Equator 300 gauging system, Renishaw introduced its Equator 500 for larger parts, with a working volume to 20 in. dia. and to 16 in. tall. Both the 300 and 500 stay accurate between 41 F and 122 F at any rate of temperature change, and are capable of scanning speeds in excess of 8 in./sec. The base of the Equator 500 supports workpiece and fixturing with a total weight limit of 221 lb. The ratio of gauging volume to footprint means that the machine is space efficient—with a footprint of 36.2 in. by 36.4 in., the 500 fits alongside production machines. Typical applications include car and truck transmission and engine casings, drive-train parts, suspension castings, pressed parts, valves, and pumps.

Building on the success of its Equator 300 gauging system, Renishaw introduced its Equator 500 for larger parts, with a working volume to 20 in. dia. and to 16 in. tall. Both the 300 and 500 stay accurate between 41 F and 122 F at any rate of temperature change, and are capable of scanning speeds in excess of 8 in./sec. The base of the Equator 500 supports workpiece and fixturing with a total weight limit of 221 lb. The ratio of gauging volume to footprint means that the machine is space efficient—with a footprint of 36.2 in. by 36.4 in., the 500 fits alongside production machines. Typical applications include car and truck transmission and engine casings, drive-train parts, suspension castings, pressed parts, valves, and pumps.