New Compact Printer Handles Wire and Powder

February 20, 2019Comments

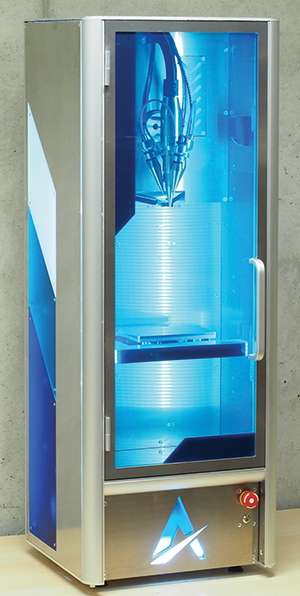

New from Additec, the μPrinter, a compact 3D metal printer that processes both wire and powder feedstock via the company’s laser metal deposition-wire powder (LMD-WP) process. Advantages, according to company officials: The ability to produce parts from wire feedstock makes operation and material handling a clean process and ensures 100-percent material efficiency; and processing powder closes the gap to conventional LMD and delivers the ability to mix alloys on the fly. Switching between wire and powder reportedly is simplified, as it does not require a nozzle change and can be done automatically.

New from Additec, the μPrinter, a compact 3D metal printer that processes both wire and powder feedstock via the company’s laser metal deposition-wire powder (LMD-WP) process. Advantages, according to company officials: The ability to produce parts from wire feedstock makes operation and material handling a clean process and ensures 100-percent material efficiency; and processing powder closes the gap to conventional LMD and delivers the ability to mix alloys on the fly. Switching between wire and powder reportedly is simplified, as it does not require a nozzle change and can be done automatically.

The μPrinter contains multiple high-power diode laser sources arranged around the central axis of the deposition head. Wire is fed through a central wire guide, while powder is fed through an annular gap nozzle around the wire guide. The machine features a controlled-atmosphere enclosure, allowing for large material variety, and a printing envelope of 120 by 160 by 450 mm.

Because wire-based coaxial deposition is not as common as powder LMD, the company developed its own process-control structure, which adjusts processing parameters on the fly and also measures the height of the individual layers, adjusting nozzle-to-part distance automatically. Further, to grant users maximum flexibility, all process parameters can be set in G-code. An included macro utility reportedly allows users to change easily the parameters for certain sections of a build.

A benefit of closed-loop control: Print quality is high both in wire and powder mode, according to company officials, and the printer can be controlled either via a locally hosted web interface or through USB.

See also: Additec - Additive Technologies

Technologies:

Video

Video