Adjusting to smaller lot sizes has led to other operational changes.

“We’re stocking more material types and plate sizes than we had in the past, and we’re doing more quoting,” Alandt says. “And we have to be aggressive—and accurate—on pricing. We upgraded our quoting process to take a more scientific and mathematical approach.”

Stack Cutting and Other Unique Jobs

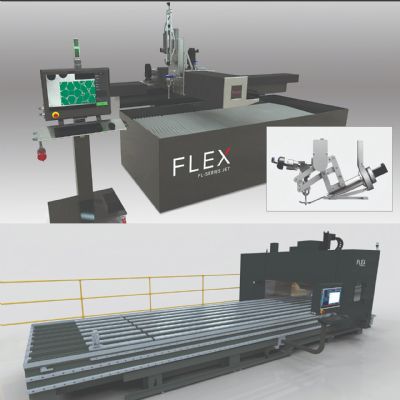

Integrating waterjet cutting into its operations came relatively easy to the Central Cal Metals team, Alandt says. But the learning curve and real trick to optimizing the return on investment has come with learning to handle the complex and challenging jobs that come in the door.

One technique the firm has become quite adept at is stack cutting, to optimize throughput. “We can stack large, heavy work,” says Alandt, “to cut two parts at a time. We’ll typically stack material 16 to 7 gauge thick, provided the blanks are larger than 12 by 12 in. With smaller work there’s a chance vibration could impact cut-edge quality and accuracy.

“We also quote a lot of odd-shaped and difficult profiles that require precise positioning under the waterjet head,” Alandt continues. “We’ve even brought in parts that were previously and incorrectly cut by other shops, and we were able to salvage the work.”

Alandt cites one example of such a job—a 3-in.-thick steel part measuring 14.5 in. wide by 96 in. long. The customer needed ½ in. trimmed from the entire length of the part.

“Waterjet cutting proved the perfect process for this job,” he says, “but it challenged our operators in precisely positioning the part under the cutting head. With the part positioned, we then set the machine to low pressure and switched off the abrasive, to etch a cut line to check alignment before cutting.”

For another unique job, cutting stairway railings from ½-in. hot-rolled steel for an architectural firm, “the customer wanted very sharp corners,” says Alandt. “While we could have laser-cut the parts, heat buildup in the corners would have required us to round the corners, which would have been unacceptable. Waterjet cutting allowed us to cut the sharper corners.” MF

View Glossary of Metalforming Terms

See also: Flow International Corp.

Technologies: Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingOmax Launches Mobile Ordering Application

Thursday, June 20, 2024