Waterjet Shines for Metals and More

March 1, 2019Comments

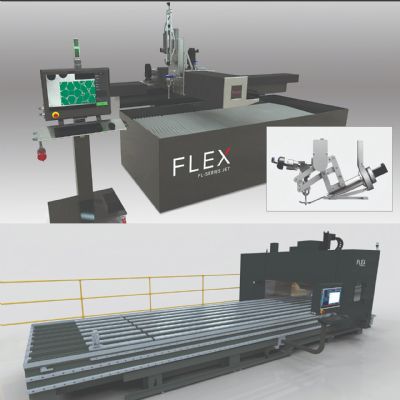

Gentle supersonic erosion and a very thin cutting stream provide manufacturers with a versatile and capable tool.

|

| In addition to mild steel and aluminum, an abrasive waterjet stream cuts exotic metals such as titanium and nickel alloys. |

The first three—exotic metals, stone and composites—use abrasive waterjet streams and the last two, pure waterjet.

Cutting Exotic Metals and AlloysAbrasive waterjet cuts many mild steel and aluminum grades, as well as exotic metals used in advanced applications, which pose problems for other cutting processes. Harder and lighter than steel, and used in applications such as aircraft and others where weight should be reduced, titanium alloys prove difficult because cutting via a mill is very slow, generates a lot of heat and quickly wears out the bit. The same holds true for nickel alloys, which remain stable at high temperatures and often find use in engines where components should not enlarge or deform with extreme heat.

When used for these materials, abrasive waterjet produces either highly accurate finished parts, or will rough cut a part to a good tolerance to later be finished on the mill. Combining waterjet cutting with mill finishing reduces processing time and saves expensive material due to the thin kerf cut of abrasive waterjet. A waterjet machine can cut titanium faster than steel, and nickel alloy at approximately the same speed as steel.

Metal fabricators not only efficiently cut alloys, but find that their machines provide opportunities in other material applications. Here are a few of those applications.

Stone

|

| Kitchen and bathroom countertops made of granite, marble, or engineered stone (usually a quartz and epoxy resin combination), often are cut with abrasive waterjet. |

Kitchen and bathroom countertops made of granite, marble or engineered stone; stone inlays, artistic pieces used to beautify hotel-lobby floors; and table tops, often are cut via abrasive waterjet.

Alternative methods for cutting stone in these applications include saws, routers and grinding. However, the abrasive waterjet’s thin stream and the fast and simple art-to-part sequence frees designers from manufacturing limitations, making detailed cutting patterns possible.

Composites

Composites, highly engineered materials usually selected for use because of their strength-to-weight ratio, are stronger per pound than metal but lighter, thus delivering a weight reduction that’s highly desirable in transportation and sporting applications.

Composites such as fiberglass and carbon-fiber-reinforced plastic present process challenges for sawing, milling, routing or burning, and usually are comprised of two components: some type of resin epoxy and cloth made of fibers. The epoxy can burn and the fibers can become damaged during cutting. Engineers using composites avoid epoxy burning, micro cracks, and delamination, as well as fiber pull out, breakage and whiskers by using abrasive waterjet. The gentle supersonic erosion process removes small amounts of material at high speed; not enough heat is generated to be transferred; and forces are localized. Abrasive-waterjet applications include trimming composite boat hulls for personal watercraft, cutting sporting goods products, trimming automobile components, and cutting huge commercial airplane parts and small airplane clips and parts.

Insulation Material

Insulation material used in HVAC and automotive applications, or in the walls of buildings and homes, can be difficult to cut, as they often utilize some type of fiberglass, either crushed or fluffy. A pure waterjet can cut fiberglass quickly, even thick fiberglass insulation used in attics.

Cement Board

Cement board finds common use as a building product. Usually 1 to 3 cm thick, it provides strength and moisture resilience, and can be formed into various shapes for building siding, substrate for wall tile, or as underlayment for floors. Cement board can be cut with a saw, the obvious cutting tool of choice at the job site. However, in the factory, cutting the cement board when in an uncured state, sometimes called a green state, is desirable.

A pure waterjet easily integrates into a manufacturing line to slit the cement board before final curing. Like stone-material applications, the abrasive waterjet can be used to cut cement board into intricate shapes after the cement board has been cured. MF

Information for this article was supplied by Flow International Corp., Kent, WA; www.flowwaterjet.com.

View Glossary of Metalforming Terms

See also: Flow International Corp.

Technologies: Cutting, Fabrication

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingOmax Launches Mobile Ordering Application

Thursday, June 20, 2024