TN Fabricator Adds Waterjet Cutting, Expands Business

March 1, 2017Comments

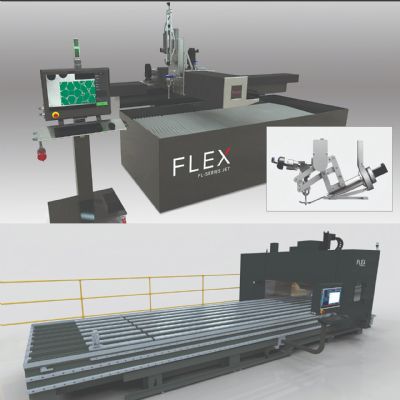

Franklin, TN, metal fabricator Murrco Fabrication, known for constructing pit boxes used in motor sports, has expanded its markets and capabilities with the addition of a new CNC waterjet-cutting system from Jet Edge, St. Michael, MN.

With the new system, Murrco debuted its waterjet cutting service in August 2016 and quickly has found work supplying Nashville-area home builders with ornamental iron products, including handrails, custom mailboxes, street signs and more. The company also is cutting a variety of race-car parts for local teams, as well as parts for its signature pit boxes.

The Jet Edge machine, capable of cutting precision parts from virtually any material, can accommodate sheet sizes to 5 by 13 ft. and offers water pressure to 55,000 psi. IGems waterjet software provides optimal CAD/CAM/nesting performance, according to Jet Edge officials.

“The waterjet service market is booming and I wanted to get involved and establish myself and my company as a waterjet service provider,” says Mike Murray, Murrco owner and president. “I plan on using my waterjet-cutting system to provide quality and accurate parts and products in a job-shop environment. As time goes on, I'm sure some new products will be added to Murrco's racing product line. Production-type work in the motorsports industry is the goal.”

See also: Jet Edge Waterjet Systems

Technologies: Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingOmax Launches Mobile Ordering Application

Thursday, June 20, 2024