Three-Headed Waterjet Warriors

May 1, 2017 work nearly around the clock at this stainless-steel service center cutting plate to 8 in. thick. Committed to providing one- to two-day turnaround for its array of customers, the center employs three waterjet-cutting machines, all with the same controller to optimize scheduling flexibility.

On the outside looking in, Metals & Services Co. appears like any other steel-service center, ready to load plate, bar and other products onto a truck for delivery to local fabricators. But from the inside looking out, this is not the typical service center. While others may offer a taste of value-added services, Metals & Services lays out the full buffet, offering an array of processing capabilities including plasma, laser and waterjet cutting, bar and plate sawing, welding, shearing, bar edging, polishing and even pre-assembly kits. Its most recent addition is a 3-kW fiber-laser cutting machine, and a 250-ton 12-ft. press brake will make its way to the Addison, IL, shop later in 2017.

|

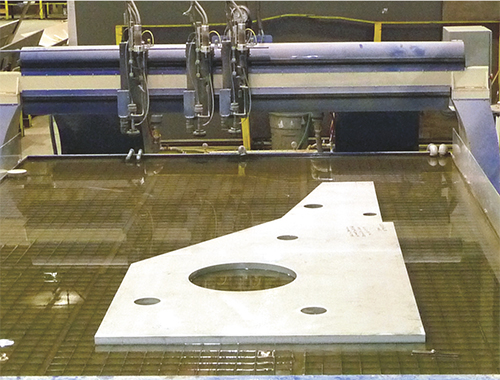

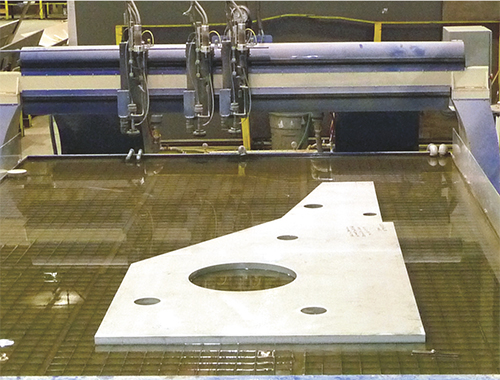

| Metals & Services Co. operates three of these three-headed WardJet waterjet-cutting machines 20 hr./day over three shifts. Using common control platforms among all three machines maximizes scheduling flexibility, according to waterjet coordinator Steve Herff. |

But the centerpiece of the 135,000-sq.-ft. shop is its trio of three-headed waterjet-cutting machines, all WardJet models. The largest of the three, and also the newest (added in 2015), features a 166- by 253-in. cutting table. The others cut on tables measuring 132 by 313 in., and 140 by 187 in.

“We’re as diversified as we can be,” says general manager Pete Fagan. “We strive to be a one-stop shop for our customers, and in fact we often take on their overflow fabrication work. I call our shop a ‘service center on steroids.’”

The firm’s customer base, notes sales executive Jayne Baessler, comprises heavy users of stainless steel—wastewater-treatment facilities, pharmaceutical manufacturers, food processors and the like.

“Customers come to us anywhere from daily to once a month,” Baessler says, “with projects ranging from major plant overhauls to one-off maintenance items. Most of what we process is 300-series stainless, although recently we’ve been working on a lot of duplex material (Type 2205 stainless steel). We carry bar, sheet and tube, and of course stock plate, from 3⁄16 to 6 in., thick; the sweet spot is 3⁄16 to ¾ in. plate.”

Waterjet’s Role

Keeping the waterjet work flowing through Metals & Services falls on waterjet coordinator Steve Herff. “Often, the customer will specify which cutting process—laser, plasma or waterjet—they prefer,” he says. “If not, we decide, based on tolerances, speed and cost. Typically, though, parts that will be machined after cutting can be plasma-cut. But if the profile is the finished product, then we opt for laser or waterjet.

“Any holes that will not be machined or reamed,” Herff continues, “are cut on the waterjets as well—such as finished holes for bolts or through which round bar must pass during assembly. We often ask the customer for the complete assembly drawings when evaluating process-processing strategies, rather than just the part drawing. With the complete assembly drawings, we can evaluate the application and recommend the optimum cutting process.”

|

The workhorse waterjet machines make thousands of inches of cuts in stainless-steel plate as thick as 6 in. week in and week out. “We’ve outfitted all of them to be powerful and large—we don’t ever want to be limited in what we can process,” says Pete Fagan, Metals & Services Co. general manager. “We specifically looked for powerful pumps to drive the three cutting heads (on each machine), without sacrificing cutting speed and quality.” The pumps of choice are Hypertherm HyPrecision 150D models, 60,000-psi dual-intensifier pumps equipped with 150-hp motors and featuring several notable control functions designed to optimize ease of use.

|

As an example, Fagan describes a recent project from a customer that typically requests plasma cutting. “However, in this case,” he says, “when we looked at the assembly drawings, we noted that the parts required a very smooth surface finish. We talked them into waterjet cutting to eliminate any post-machining operations.”

A high-profile job completed recently by the service center had it cutting ¾-in. stainless plate for Omaha, NE, fabricator Puritan Manufacturing, contracted to build a massive 55,000-lb. sculpture for the University of Nebraska’s sports arena. The sculpture, describes Herff, combined two-side-polished plate with holes cut in some sections through which polished tubes were to be inserted.

“Here I worked closely with the customer to determine the optimum clearance between the tubes and the hole diameter to prevent damaging the surfaces during assembly,” he says. “Waterjet cutting the plates allowed us to meet tight tolerances and achieve the desired surface finish.”

True Workhorses

The trio of waterjet machines are true workhorses. The shop typically runs 50-mesh garnet, suitable for nearly all of its stainless-steel plate-cutting work. For particularly thin-gauge sheetmetal and more precise cuts, it’s equipped one of the three machines with dual garnet hoppers.

“We load that second hopper with 120-mesh garnet,” says Herff, “for fast changeovers. We also use that fine garnet to cut aluminum.”

“We run the machines 20 hr./day over three shifts,” adds Fagan. “We’ve outfitted all of them to be powerful and large—we don’t ever want to be limited in what we can process. We specifically looked for powerful pumps to drive the three cutting heads (on each machine), without sacrificing cutting speed and quality.”

The pumps of choice are Hypertherm HyPrecision 150D models, 60,000-psi dual-intensifier pumps rated for a maximum orifice diameter of 0.025 in. They’re equipped with 150-hp motors and feature several notable control functions designed to optimize ease of use. These include what Hypertherm calls advanced intensifier monitoring, for early detection of leakage; an enhanced maintenance interface along with a web-based interface for remote access to system and maintenance performance; and control of intensifier settings during pump operation.

Cutting

Cutting