Die Shop Assigns Waterjet-Cutting Machine to Carve Out Die Sets and Stripper Plates

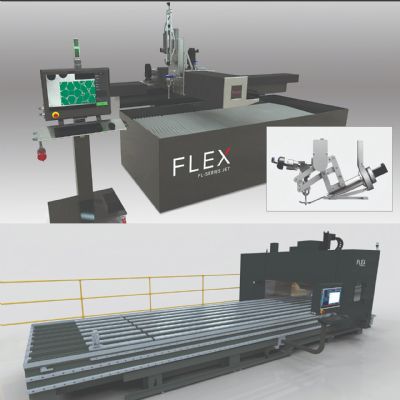

June 1, 2009Comments MRG Tool and Die, Faribault, MN, manufactures metal-stamping dies, plastic injection molds, jigs and fixtures, and also offers production stamping and machining services. When the firm recently went looking to produce parts more quickly and efficiently, as well as reduce material costs, MRG sought to implement state-of-the-art cutting technology. It ultimately acquired a waterjet-cutting machine from Flow Intl., Kent, WA.

|

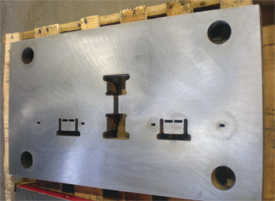

“Machining molds and dies, we used to rough things out that we’d finish-machine later,” says Rebecca Gramse, an engineer at MRG. “We wanted to do a better job by cutting more quickly and efficiently as well as save money on material. Flow’s 87,000-psi waterjet-cutting machine helps us accomplish those goals. We’re now cutting die sets, stripper plates and aerospace parts that involve different fixturing and tooling.”

Using the new machine, “we’ve realized a tremendous improvement in productivity,” adds Gramse. “For example, cutting die-set plates, what previously took 25 hr. to accomplish now takes just 15 hr., with nice edge quality.”

Flow Intl.: 253/850-3500; www.flowcorp.com

See also: Flow International Corp.

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingOmax Launches Mobile Ordering Application

Thursday, June 20, 2024