Cutting with Lasers and Waterjets—The Right Process at the Right Time

December 1, 2009Comments

Article submitted by Mitsubishi Laser and MC Machinery Systems, Inc., Wood Dale, IL: www.mitsubishi-world.com.

|

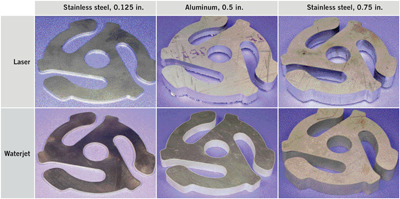

| Sample parts from stainless steel and aluminum alloys, in three thicknesses, demonstrate the edge-quality differences when cutting with laser and waterjet. |

Today’s fabricators are looking for more than just speed. They need metal-fabricating equipment that will add capabilities and flexibility, enabling them to bring in new business. Dynamic applications in today’s hottest industries are using more interesting and unusual materials than ever before, and many metal fabricators are being called on to cut more exotic alloys, even composites. Among the tools of the trade: laser-cutting and waterjet-cutting systems.

Laser-cutting machines use a high-power laser beam to cut through sheet and plate.

Twenty years ago, lasers were capable of cutting 1⁄2-in. steel at 1 to 2 in./min. Today, systems can cut 1⁄2-in. steel at 80 in./min. Automation, increased resonator power, and improvements in controllers have revolutionized the laser industry.

Lasers can quickly and easily switch from one metal alloy to the next with little downtime. Also, automation equipment helps fabricators achieve lean manufacturing by increasing output while decreasing or eliminating labor costs.

Waterjet cutting represents one of the fastest-growing technologies used in the metal-fabrication industry. The process uses a high-pressure stream of water, with an added abrasive such as garnet, to make the cut. No heat is generated during waterjet cutting, eliminating the risk of material distortion.

Waterjet cutting suits nearly every material, including glass, ceramic, wood, stone, plastic and rubber. This versatility can help niche suppliers branch out of small market segments and appeal to a much broader customer base.

The Right Process for the Job

Laser- and waterjet-cutting machines offer a good life expectancy since they do not use dynamic machining forces and they do not make direct contact with the workpiece during cutting. So, when both technologies can do the job at hand, how does a fabricator determine which process to use? Understanding a few key factors can help simplify the decision.

• Speed and thickness—Lasers are well-suited to cutting metal-alloy parts as thick as 1⁄2 in., but they can cut steel plate to 11⁄2-in. thick. On the other hand, waterjets can cut plate to 6 in. Lasers often have a speed advantage over waterjets. For example, on 1-in.-thick carbon steel, a waterjet with a pump that develops 60,000 PSI and equipped with a 0.014-in. orifice and a 0.030-in. nozzle, and consuming abrasive at a rate of 1.2lb./min., cuts at 2.9 in./min. Comparatively, a 4-kW laser with a 2-mm coaxial nozzle, and using oxygen as the assist gas at 8.4 PSI, can cut more than eight times faster at 24.5 in./min. Waterjet, however, can cut through significantly thicker materials, and alternative materials, with ease. For example, cutting the sample parts shown in the photos, a waterjet machine cut the same part from 0.75-in. foam rubber in 45 sec., from 0.375-in. granite in 198 sec., and from 0.625-in. glass in 126 sec.

• Material—Lasers can process materials other than metal alloys, but this doesn’t mean they should. On plastics and rubbers, for example, laser cutting releases unappealing byproducts, while waterjet can easily cut these materials without releasing hazardous byproducts.

Highly reflective materials such as aluminum and copper also are particularly difficult for lasers to cut. For example, the cutting speed for laser and waterjet are nearly identical on 1⁄2-in. aluminum, but edge quality is significantly better with waterjet (see photos).

A laser performs best on smooth surfaces; textured surfaces can alter the flow of the assist gas and disrupt the beam’s focus. A waterjet, on the other hand, does not discriminate when it comes to reflectivity or texture.

• Finish—The heat from laser cutting produces a small heat-affected zone (HAZ) near the cut, which could require secondary finishing depending on finish requirements. Waterjet does not create an HAZ. In addition, waterjet cutting delivers a smooth edge finish without jagged edges, slag or burrs, eliminating the need for secondary finishing processes such as grinding. Also, because the process does not impart heat to the workpiece material, it will not distort the parts, which then can be easily stacked to increase productivity. MF

View Glossary of Metalforming Terms

See also: MC Machinery Systems

Technologies: Cutting