Zero Taper is Possible

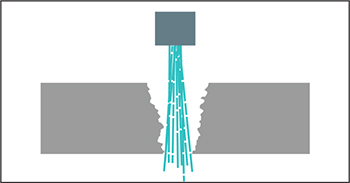

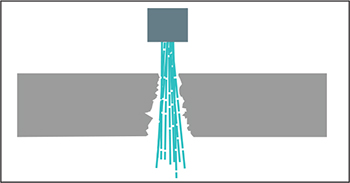

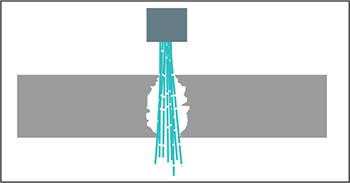

Some machines can remove V-shaped and reverse taper simply by tilting the cutting head to compensate. For example, Omax Tilt-A-Jet technology allows for automated taper compensation, using a predictive model to calculate taper in the kerf at each portion of a cutting path. The software commands the nozzle head to tilt in vertical alignment with the part edge, resulting in taper on the scrap side of the material being cut. The jet continuously adjusts at thousands of points per inch along the cutting path, and the software controls cutting speed at each point while optimizing acceleration and deceleration. This allows for more precise cutting and significant increases in cutting speed. The result: a square edge.

|

| Fig. 4—To better combat unwanted taper, use the highest-quality abrasive available. And, experiment if necessary. If experiencing taper with an 80-mesh abrasive, try a 120- or 150-mesh. |

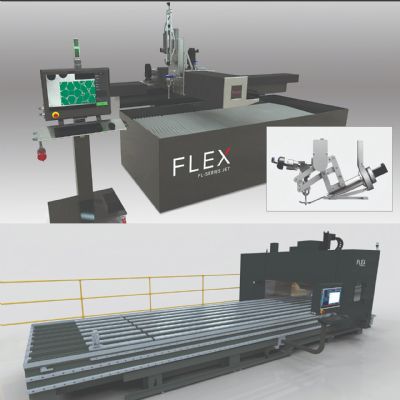

Another product, A-Jet, also from Omax, assists in the elimination of taper. The A-Jet bevel cutting head allows for automated, articulated taper compensation and enables creation of complex 3D shapes.

Minimize Taper Without Accessories

Even without the use of automated articulated cutting heads, operators still can mitigate taper. Today’s waterjet software often offers built-in taper-compensation options as well as improved nozzle controls. In addition, operators can take steps to reduce or eliminate taper.

Adjusting cut qualities represents the easiest and least-intrusive method for adjusting taper without using accessories. Slow down the cutting head by raising the cut quality in areas that must exhibit zero taper. Keep in mind that slowing the cutting head will lead to slower cutting times and increased abrasive usage.

Since thinner materials tend to exhibit the greatest amount of taper, try stacking. Taper usually is most pronounced in material thicknesses of less than 0.125 in. If available, use a stack-height calculator in the machine’s control software to determine the optimum number of sheets to stack in order to produce the most parts in the least amount of time.

Note that standoff matters. The jet stream will flair once it exits the nozzle. To mitigate this, maintain a recommended distance between the nozzle and the material being cut. Usually, standoff measures between 0.03 and 0.08 in. depending on the diameter of the nozzle. The closer the nozzle to the material, the less the jet stream will spread, and the less taper it will produce.

Use the highest-quality abrasive available. If experiencing taper with an 80-mesh abrasive, experiment with a 120- or 150-mesh. Lower-quality abrasives tend to have less-consistent particle sizes. In the end, this comes down to purchasing abrasive from a reputable distributor.

Another tip: Guarantee that the Z axis is perpendicular to the material in both the X- and Y-axis directions. Use a pitch indicator to ensure a cutting-head angle of 90 deg. relative to the cutting table. In addition, be sure to properly seat the machine’s mixing tube, otherwise the machine will not cut with an accurate Z axis. For machines equipped with an Omax A-Jet or Tilt-A-Jet, operators can use the Calibrate Perpendicular feature available in the Intelli-Max Make Setup menu.

Taper may result from uneven wear in the mixing tube. This is not a function of the motion-control equipment, but rather a consequence of how the abrasive wears inside the mixing tube. Rotating the mixing tube 90 deg. for every 8 to 10 hr. of cutting time allows the mixing tube to wear more evenly and last longer, while preventing taper.

Keep Learning

Lastly, to keep unwanted taper at bay, stay abreast of current techniques by following manufacturing and trade blogs, social media and magazines. Become comfortable with your abrasive-waterjet machine, and learn how it behaves and how to work its idiosyncrasies. And, measure parts periodically to ensure accuracy. Knowing how a particular machine will react to certain materials under certain conditions is the best method for predicting taper outcomes. MF

Information for this article was supplied by Omax Corp., Kent, WA.

View Glossary of Metalforming Terms

See also: Omax Corporation

Technologies: Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingOmax Launches Mobile Ordering Application

Thursday, June 20, 2024