An End to Edge Taper

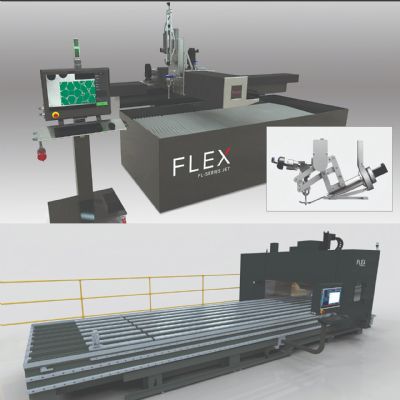

Wolfe’s new waterjet machine not only produces clean edges, it features Flow’s Dynamic Waterjet technology that does away with edge-taper concerns. The technology is based on mathematical modeling to predict taper angle, then compensating by adding the required wrist articulation. This action is managed by Flow’s FlowMaster Windows-based control system, based on user-input process parameters such as material type and thickness, cutting speed and desired angle quality. The cutting process, with edge-taper compensation, then occurs without intervention by a Wolfe programmer or operator. It pushes the taper to the scrap side of the workpiece to ensure a precise part-edge profile—four to six times more precise than a conventional waterjet, say Flow officials, with a much higher cutting speed.

“That’s critical to ensuring that we continue to meet lead-time requirements,” says Wolfe, “which of course have been tightening.”

Clean Cuts Eschew the Need for Sanding

Wolfe employs 25 in the shop and another 80 or so in the field working on installation and maintenance projects at several sites at any one time. It numbers 120 active customers and processes material from 26 gauge to 1.25 in. thick. As much as 80 percent of the material it cuts moves on to be formed and/or welded, and waterjet-cut work in particular rarely if ever requires any additional cleanup.

Which Abrasive is Right for the Job? Wolfe feeds its waterjet-cutting machines a general-purpose alluvial-garnet abrasive (Barton 80 HPA, at about 1 lb./min.), which “provides good edge quality and solid cutting performance,” says Barton literature. Also available to fabricators are more aggressive garnets for higher-speed applications and a more fine garnet that optimizes precision and generates the smallest possible kerf. How do you know which garnet abrasive best-fits the jobs at hand? Well, seemingly like every other sheetmetal-job-shop process, there’s an app for that. Check out the Barton Abrasive Value Calculator, available for iPhone and iPad, which generates a cost comparison of available garnets based on a bevy of parameters. These include cost, cutting speed and hourly shop rate.

“Before we added the second waterjet machine,” shares Alexander, “we often were forced, due to capacity constraints, to cut some of the stainless steel on our plasma-cutting machine and then drill any of the holes that were required. The secondary hole-drilling process diminished throughput, not to mention the need to sand off any edge discoloration from plasma cutting. That’s all become a thing of the past with the new waterjet machine.”

We saw several examples of the quality of the work coming off the new waterjet machine. Included were parts being cut from Type 304 stainless-steel sheets (5 by 10 ft.) for fabricating chutes and ductwork for a General Mills food-processing plant; and copper inserts for furnace nozzles, fabricated for a company that gas-atomizes metal powder.

“When we were automotive-focused,” says Wolfe, “it often was difficult to differentiate ourselves from the several other shops around that can do that kind of work. Now, thanks in part to becoming experts in stainless-steel fabrication, we can make a name for ourselves and separate from the pack.” MF

View Glossary of Metalforming Terms

See also: Flow International Corp.

Technologies: Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingOmax Launches Mobile Ordering Application

Thursday, June 20, 2024