Sole-Source Systems May Be Best Option

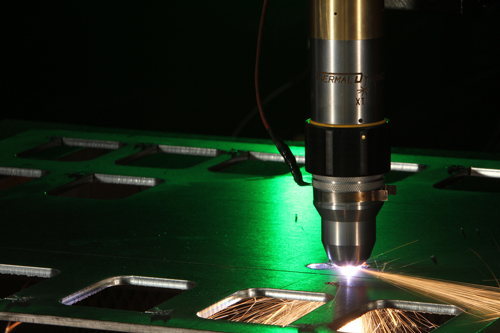

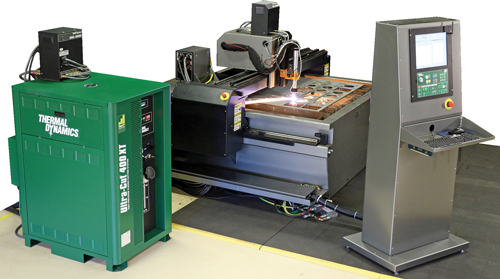

A plasma cutting system typically consists of a table, power supply, gas boxes, the torch, height control and the CNC package. Dating back a decade or more, Ott notes, many times these separate components were mixed and matched to produce the system. While integration from separate sources still occurs, Ott believes that an integrated system from a sole source provides the most effective solution, offering improved cut quality.

“In the past,” he says, “an equipment OEM bought a power supply from company A, a height control from B and the CNC package from C, with the OEM tasked with combining these components. An OEM really needed to understand each of these components in order to produce a well-performing system. For example, the heart of the system, the CNC package, controls the power supply, the plasma system and the height control. The height-control system normally comes with little or no performance information, as all of that must come from the plasma-system manufacturer. Often, the plasma-system provider supplied limited information on that to its fabricator customers. This held true across the other components as well—not enough information transfer between the component manufacturers and the OEMs. So system performance suffered.”

Plasma Cutting Sweet Spots • Sheet thicknesses from 2 to 6 mm • Thicker plates • Simple internal contours and cut details

Hole sizes and locations, important cutting parameters, provide an example of the benefits of a single-source integrated system.

“Hole optimization requires a very close interconnection of the CNC, the height control and the plasma system,” Ott explains. “Without that, a user couldn’t repeatedly produce the same holes.”

Consider a Cutting Family Affair

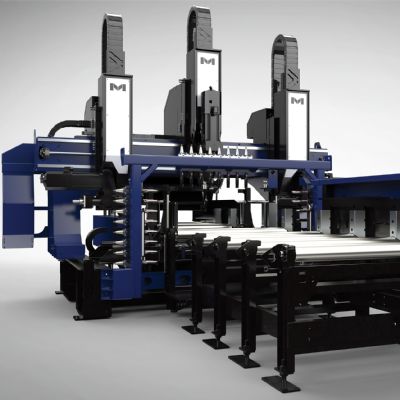

Given enough volume in thin and thick material, adding plasma cutting systems to on-hand laser cutting capability, and vice versa, may prove beneficial. Material would route to each type of machine based on criteria such as that suggested above.

“A fabricator may need to cut 6-mm-thick stainless steel or aluminum, for example, requiring small, intricate shapes but not needing an intricate outer contour,” says Ott, providing an example of where the two technologies can work together. “With high labor and operating costs, fabricators don’t want to waste valuable time making a long cut with a laser. Do that on the plasma machine, then switch to the laser.”

Here, Ott points out machines employing both plasma and laser cutting technology, as well as machines combining plasma and waterjet cutting, thus enabling the advantages of each technology in a single unit. Fabricators perhaps with limited floor space may consider such a system, with a lower cost than that of two separate machines. MF

View Glossary of Metalforming Terms

See also: Thermal Dynamics

Technologies: Cutting