Robotic Cell for Beam Cutting

March 20, 2024Comments

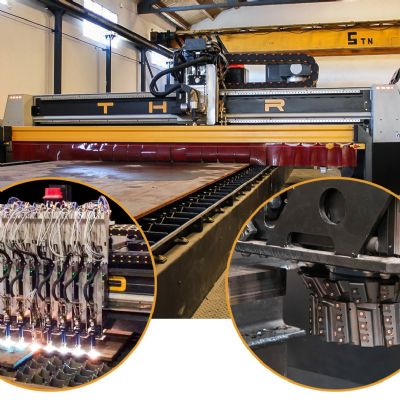

Beamcut Systems, part of Machitech Automation Group, recently updated its BC25, a user-friendly, versatile, robotic 3D CNC cell and platform for cutting metal parts and profiles for virtually any structural-steel shape. Employing high-definition Hypertherm plasma technology and Fanuc robotics, the BC25 is a fully automated six-axis beam-cutting system. It is designed to improve overall repeatability and accuracy while eliminating bothersome layout work before cutting, and time-consuming and costly grinding after profiles are cut.

Beamcut Systems, part of Machitech Automation Group, recently updated its BC25, a user-friendly, versatile, robotic 3D CNC cell and platform for cutting metal parts and profiles for virtually any structural-steel shape. Employing high-definition Hypertherm plasma technology and Fanuc robotics, the BC25 is a fully automated six-axis beam-cutting system. It is designed to improve overall repeatability and accuracy while eliminating bothersome layout work before cutting, and time-consuming and costly grinding after profiles are cut.

The BC25 cell includes a small-footprint automated in-feed and out-feed system as well as a photo-laser measuring device that allows split-second profiling and positioning to deliver a precise cut. A simple-to-use Windows-based operator control system does not require special operator training, and Beamcut Soft software uses DSTV files from 3D-profiling software and 2D DXF AutoCAD files. Once files are imported, Beamcut Soft automatically simulates the cutting sequence, then an automatic cutting trajectory is created and verified on the drafting computer instead of the machine.

For safe operation, the BC25 incorporates a safety enclosure and smoke trap, and a safety cabinet complies with OSHA safety standards. An available option: a dust collector to remove smoke and dust particles.

View Glossary of Metalforming Terms

See also: Machitech Automation

Technologies: Cutting