CNC Plasma Cutting Streamlines Helical-Pile Fabrication

February 19, 2025Comments

Sealevel Construction, Inc., in Thibodaux, LA, has been serving the U.S. Gulf Coast region since 1997.

Sealevel Construction, Inc., in Thibodaux, LA, has been serving the U.S. Gulf Coast region since 1997. Initially a small public-works firm, Sealevel quickly grew into a turnkey, civil-construction company serving the municipal, industrial and marine markets, and employing more than 300 people.

Industrial division manager Tyler Glaze attributes the firm’s growth to its expansion into industrial facilities, where Sealevel performs site development, pours structural concrete and installs all types of deep foundations, including the fabrication and installation of helical-shaped steel piles.

After a few years of installing helical piles, company

management decided to begin manufacturing them inhouse. The team initially

experimented with manual production by cutting piles with a bandsaw or torch

and then drilling out the bolt holes, but that process caused bottlenecks.

Although making a square cut on one end of each pile was fairly

straightforward, miter cutting the opposite end proved more complex. And when

it came to drilling holes, dimensional tolerances were tight and difficult to

maintain manually.

After a few years of installing helical piles, company

management decided to begin manufacturing them inhouse. The team initially

experimented with manual production by cutting piles with a bandsaw or torch

and then drilling out the bolt holes, but that process caused bottlenecks.

Although making a square cut on one end of each pile was fairly

straightforward, miter cutting the opposite end proved more complex. And when

it came to drilling holes, dimensional tolerances were tight and difficult to

maintain manually.

“It took forever to lay the piles out, manually cut them and then weld the helical sections to the piles, because the cuts weren’t clean,” says Glaze.

Investing in CNC Pipe Profiling

Sealevel, refusing to sacrifice quality and delivery schedules, knew it needed to integrate CNC machinery into its fabrication process, leading it to explore CNC pipe-profiling technology. Its fabrication facility already had been operating a CNC plasma-cutting table and CNC beam processor, so the team was well aware of the value CNC could bring to its processes. A CNC pipe profiler not only could help with the helical piles, the team believed, but it also could support fabrication of the pile jackets—a sleeve used to protect the piles from ground movement—where complex copes, miters and bevels are common.

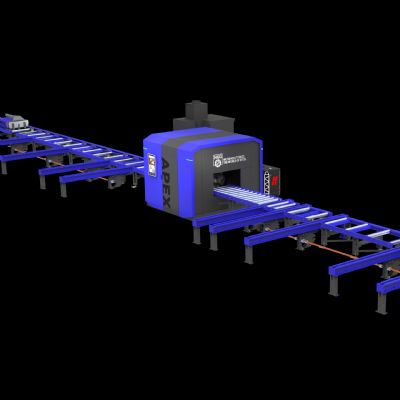

Soon after, Glaze opted to purchase a used CNC pipe-cutting machine, a ProCutter 600 from HGG Group rated for pipe to 24-in. dia., and which can cut a pipe in 30 sec. that would take two workers 45 min. to cut manually. Using the machine to cut pipes accurately and precisely the first time around, Sealevel fitters and welders were able to shift their focus to fitup and welding rather than on laying out, cutting and fixing mistakes.

The ProCutter 900 RB can automatically kick out pipes to its

front buffer table as needed, minimizing forklift traffic in the shop. Forklifts

in the shop were becoming somewhat of a hazard, Glaze shares, as moving raw

material, work in progress and finished parts to their respective destinations

meant lots of opportunities for collisions. Now, thanks to the

material-handling automation on the new pipe-profiling machine, the floor is

clear, eliminating safety incidents. Eventually, Glaze wants to automate the

shop such that a forklift only loads the pipes into the infeed rack and then

offloads finished parts directly to the truck.

The ProCutter 900 RB can automatically kick out pipes to its

front buffer table as needed, minimizing forklift traffic in the shop. Forklifts

in the shop were becoming somewhat of a hazard, Glaze shares, as moving raw

material, work in progress and finished parts to their respective destinations

meant lots of opportunities for collisions. Now, thanks to the

material-handling automation on the new pipe-profiling machine, the floor is

clear, eliminating safety incidents. Eventually, Glaze wants to automate the

shop such that a forklift only loads the pipes into the infeed rack and then

offloads finished parts directly to the truck.