Mixing Machines and Metal Art

August 1, 2012Comments

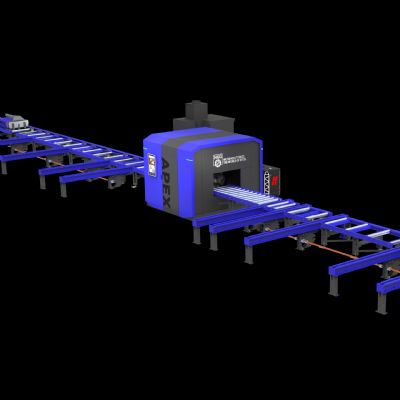

When metal artist Dick Roberts discovered Torchmate CNC plasma-cutting machines, the hours he spent hunched over aviation snips, and the days of laborious repetition with a hand-held blowtorch, went out the window. Working out of his garage in Fort Myers, FL, Roberts fabricates intricate steel, copper, aluminum and stainless-steel art pieces. His Torchmate 2—a 4- by 4-ft. cutting machine—is the primary weapon in his arsenal of fabrication equipment.

“Instead of spending days cutting parts out individually,” he says, “I can make them all at once with a push of the button. And, the CNC machine eliminates the manual and tedious part of the metal-art process.”

Since purchasing his Torchmate (now a Lincoln Electric company) in 2007, Roberts has received a mostly self-taught crash course in CNC machining, and today he is passing that knowledge on to a new crop of metal artists. In fact, as his metal-art career has taken off, he’s featured his work on his website and used his videography skills to produce a series of instructional videos on CNC machine use. In a three-part series, Roberts explains the origins of metal art, how to set up a CNC machine and how to design in CAD. Check it out at www.metalartbydickroberts.com.

Torchmate: 866/571-1066; www.torchmate.com

See also: Lincoln Electric Co.

Technologies: Cutting