New Dust Collector Optimized for Fiber Laser Cutting

September 10, 2020Comments

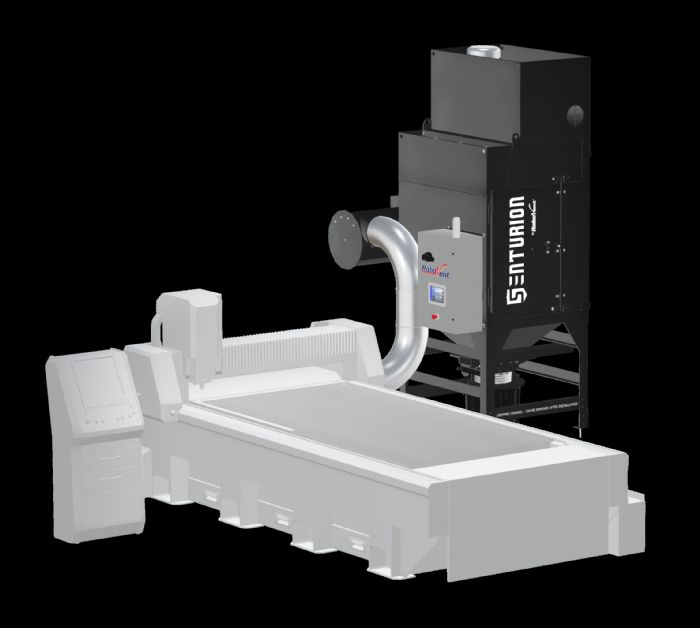

The faster cutting

speeds of fiber laser machines create new challenges for laser cutting dust

control, leading RoboVent to develop the Senturion, optimized for the volume

and type of dust produced by fiber laser cutting.

The faster cutting

speeds of fiber laser machines create new challenges for laser cutting dust

control, leading RoboVent to develop the Senturion, optimized for the volume

and type of dust produced by fiber laser cutting.

Senturion addresses the challenges of fiber laser cutting dust collection with several adaptations, including a powerful and efficient motor-blower combination to ensure adequate airflow for laser cutting applications. Also, a lower air-to-cloth ratio (more filter media per CFM of air) handles large volumes of dust, and an advanced pulsing system prevents dust from becoming embedded in the filter media. The RoboVent Pleatlock filters used with the Senturion offer more filter media to capture more dust with less loading.

Senturion also comes standard with RoboVent’s touch-screen control system and SafeSensor particulate monitor, which detects leaks past the filter and shuts the collector down if a leak is detected. The rugged, powerful plug-and-play system is designed to keep up with the demands of fiber laser dust collection in high-production manufacturing facilities.

“Fiber lasers create higher loads very fine particulate, which creates challenges for the fume collection industry,” says Rick Kreczmer, president of RoboVent. “Senturion has been designed to handle the high cutting speeds and rapid filter loading inherent to fiber lasers, so they deliver better performance for end users.”

See also: RoboVent

Technologies: Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

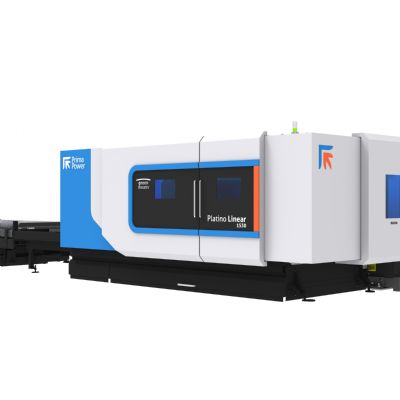

CuttingIntegrated Plate Processing Combined With Automated Material...

Friday, June 20, 2025

Cutting

CuttingLaser Cutting Automation With Smart Material Handling

Wednesday, June 18, 2025