Targeting High-Volume Cutting to 1-In.-Thick

Though the new 20-kW machine will cut 1-in. plate with pure nitrogen, Shrock reports that by using mix gases, “we can add a small amount of oxygen into the nitrogen, delivering a faster and cleaner cut. But again, with the 20-kW machine we can use pure nitrogen or a nitrogen/oxygen mix to cut all the way to 1-in. thicknesses—cooler and faster, potentially four to six times faster in some situations than with pure-oxygen cutting. With the ability for fast and clean cuts, right we now are pushing for high-volume production contract work on material between 7 gauge and 1 in. thick.”

Though the new 20-kW machine will cut 1-in. plate with pure nitrogen, Shrock reports that by using mix gases, “we can add a small amount of oxygen into the nitrogen, delivering a faster and cleaner cut. But again, with the 20-kW machine we can use pure nitrogen or a nitrogen/oxygen mix to cut all the way to 1-in. thicknesses—cooler and faster, potentially four to six times faster in some situations than with pure-oxygen cutting. With the ability for fast and clean cuts, right we now are pushing for high-volume production contract work on material between 7 gauge and 1 in. thick.”

With the new machine’s high laser power, rapid acceleration and the ability to cut cleanly in the above-mentioned material-thickness range, “we can do something that we believe no one else in the industry can,” Shrock offers. “We can pierce a 1⁄4-in.-dia. hole through 3⁄4-in. material, so clean and fast using nitrogen that we can tap without a secondary operation. Normally, fabricators have to cut 3⁄4-in.-thick material with oxygen, but that doesn’t deliver a hole diameter and shape precise enough to tap it—the tap would break off. Secondly, the hardened surface would break the tap just by itself. Our material remains soft because we cut so quickly and coolly that the carbon steel does not crystalize.”

Aiding in this capability, the 20-kW Eagle machine, like the 15-kW Eagle, offers cutting tolerances to 0.001 in., considerably better than other machines in the shop.

Less Downtime

For increased uptime, Shrock Fabrication’s 15-kW machine includes automated part handling. As for the 20-kW machine, “not right now, as we have sufficient time for two people to separate parts from the sheets and unload that machine,” Shrock says.

The 15- and 20-kW machines, reports Shrock, also offer a design characteristic that contributes greatly to uptime.

“I have never replaced the protective glass laser lens on the 15-kW machine (the lens closest to the cutting surface),” he says. “Some lasers require replacement of that lens almost daily, or weekly.”

Why no replacement? The protective lens sits nearly 14 in. above the cutting surface—higher than most other machines on the market, according to Shrock.

“Protective-glass-lens replacement takes 10-15 min., but every time that chamber is opened for replacement brings the risk of a microscopic piece of dust landing on the protective lens and requiring another replacement when that lens fails,” he says. “With the protective lens located so high above the cutting surface, spatter doesn’t travel up that high and burn onto the glass, so we have yet to replace it.”

Adding the 20-kW machine to its laser cutting stable, Shrock Fabrication hopes to add another 1 million lb. worth of laser cutting per month.

“That's my next goal: Grow with the 20-kW machine, gain some diversity and take on heavier-plate cutting,” Shrock says. “We cut close to 1 million lb. now, and I think we could double it if we added that heavy-plate cutting.” MF

View Glossary of Metalforming Terms

See also: Fairmont Machinery/Eagle Laser

Technologies: Cutting

To meet its high-volume needs in sheet metal fabrication, Shrock Fabrication, in a 37,000-sq.-ft. manufacturing operation with 35 employees, relies heavily on its laser cutting equipment and capabilities.

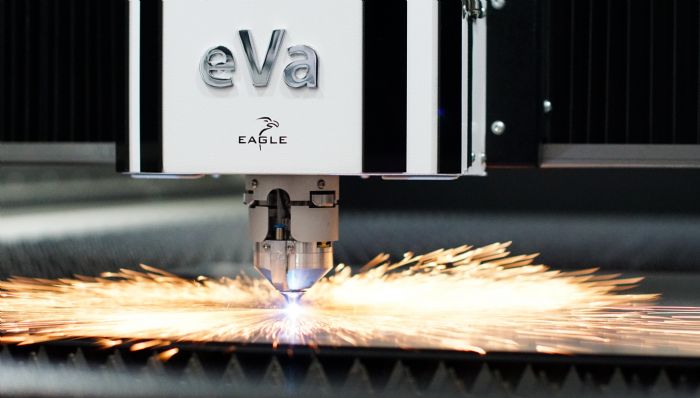

To meet its high-volume needs in sheet metal fabrication, Shrock Fabrication, in a 37,000-sq.-ft. manufacturing operation with 35 employees, relies heavily on its laser cutting equipment and capabilities.  Both the 15- and soon-to-be-installed 20-kW machines are part of the Eagle iNspire series, which offers a top traverse speed of nearly 14,000 in./min. and 6-g acceleration. Design attributes in this series include a polymer-granite base structure, carbon-fiber bridge, linear-drive motors on all axes and rapid optical encoder feedback, which help achieve the rapid acceleration and the ability to cut more than 9 holes/sec.

Both the 15- and soon-to-be-installed 20-kW machines are part of the Eagle iNspire series, which offers a top traverse speed of nearly 14,000 in./min. and 6-g acceleration. Design attributes in this series include a polymer-granite base structure, carbon-fiber bridge, linear-drive motors on all axes and rapid optical encoder feedback, which help achieve the rapid acceleration and the ability to cut more than 9 holes/sec.