Fiber Laser Makes the Cut at HVAC Manufacturer

June 1, 2012Comments

From its founding in 1960 in the back of a garage in northern Alberta, Canada, ECCO Manufacturing has evolved into one of North America’s largest manufacturers of HVAC sheetmetal products.

From its founding in 1960 in the back of a garage in northern Alberta, Canada, ECCO Manufacturing has evolved into one of North America’s largest manufacturers of HVAC sheetmetal products. The company employs approximately 600, who work out of a combined 500,000 sq. ft. of manufacturing and distribution space in facilities in Langley, British Columbia, Calgary, Alberta, and Kent, WA.

New Plant, New Fiber Laser

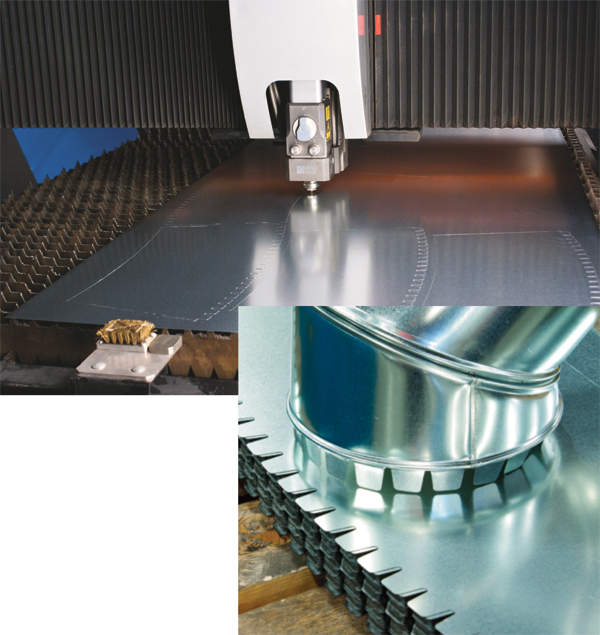

In 2010, the ECCO Calgary facility moved to a new manufacturing plant and distribution center, comprising 7 acres under one roof. Shortly after it moved in, the plant welcomed a new fiber-laser cutting machine—a Platino 2D flat-sheet and plate processing machine from Prima Power. The laser purchase culminated a long and thoughtful equipment-decision process, says David Mackay, assistant plant manager.

“The process started back in 2008,” recalls Mackay, “when we were quoting on a fairly large and cost-sensitive job. We did some investigating and discovered that on some high-volume items, we could save as much as five or six percent per part by using laser cutting rather than band-saw cutting. That prompted our initial and serious discussions about purchasing a laser.”

Mackay explains that prior to purchasing the Platino fiber laser, the ECCO facility produced most of its contoured parts on its five vertical band saws. “We still perform stack cutting of the contours on the band saws, after shearing the material to the blank size we need,” notes Mackay. “We also have punch presses, but our thin-gauge material is a challenge for the presses. With a punch press, the clamps that hold the material and shift it side to side and front and backs can cause the material to buckle. To avoid buckling, we have to slow the punch press down. Cutting on the laser, the material remains stationary while the cutting head moves—no worries about buckling.”

ECCO finds that the accuracy and the small cut width of the fiber-laser beam is so fine that it’s been able to be more creative in how it designs its products, including the use of tabs. And, being able to round the corners of the tabs means that installers have less chance of cutting themselves.

Why a Fiber Laser?

“During our research,” says Mackay, “we became sold on the fiber laser. We learned that the machines have fewer consumables than CO2 laser-cutting machines, that the technology is perfect for cutting thin material, and that we can use our shop air for cutting purposes, eliminating the need for oxygen or nitrogen. Including costs for all of the consumables, power and other operating costs, we have seen quotes of $15/hr. for operating a comparable CO2 laser (excluding labor), compared to $5/hr. with a fiberoptic laser.”