“We’re all in the same boat,” he says. “Materials costs are skyrocketing. Shipping costs are soaring. Everywhere you look, it costs more to do less.”

The company has set up a website, www.nelp.com, to get the word out about its capabilities, and has upped its commitment to sales, two areas that McCullock felt needed immediate attention.

To handle more business and best serve customers, the company also has dedicated itself to having on hand state-of-the art equipment.“In the last year we have put more money back into the company than was put back in the last 10 years,” McCullock says. That includes a new Rofin-Sinar Nd:YAG laser marker. “We used to do laser marking and got away from it,” he says, “but now we see it as a value-added process that can be brought in and be productive right away.”

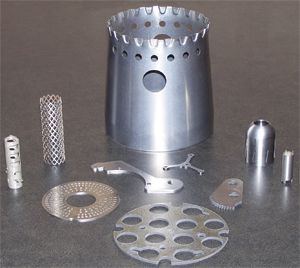

With the new laser marker New England Laser Processing can perform standard and custom marking, including serial numbers for medical devices, and handle a range of metallic surfaces and plastics as well as flat or curved parts.

The company also upgraded its CAD/CAM programming software to current versions and replaced one of its old laser cutters with a new machine with more laser power than the 1700-w unit it replaced, and able to handle sheets to 60 by 120 in.

“We had difficulty being competitive on thicker material with only 1700 w of power,” McCullock offers. “That’s part of our philosophy that we need to make things happen for our customers and need equipment that allows us to process jobs in a timely and cost-effective fashion. If our employees, be they office personnel, CAD programmer or setup technician, struggle with antiquated software or shop-floor equipment that is tedious to use, it slows us down. So we’ve made a tremendous push to make the company a more efficient fabricator.”

Raw-material prices are a big driver for that push.

“I remember when it used to cost more to laser cut the part than to purchase the material,” McCullock says. “Now we are seeing that the reverse is true: We spend four or five times more for the material than we do to turn it into a part. That is horrific. We deal with it by trying to stay ahead of the technology curve. We have equipment that will move quickly enough to make part production more cost-effective. Though cost savings may be a small percentage, any savings is beneficial. A small prototype run may not make a big impact, but if that prototype run turns into a production run, saving 20 cents on a part can make or break a job for us and the customer. We are trying to keep ourselves lean, trim the fat and be as cost-effective as possible so that our customers can stay competitive.”

But technology upgrades only lead to success if employees have the skills to use them correctly, according to McCullock.

“Personnel sometimes can be overlooked,” he says. “You need stability and rock-solid results from employees in an operation, and we have that.”

And New England Laser Processing plans to hire skilled, seasoned personnel to run new equipment as it is brought into the company. MF

View Glossary of Metalforming Terms

See also: Rofin-Sinar, Inc.

Technologies: Cutting