Accurate Laser Trimming Improves Fitup, Simplifies Assembly

January 1, 2010Comments Contract metal fabricator Pickwick Manufacturing Services, Cedar Rapids, IA, is saving its customers time and money thanks to the use of a robotic 3D laser-cutting cell.

|

“The FabriGear’s ability to cut precise, tight joints and tabs and slots in the material saves hours of labor,” says company president Walt Corey. “A recent customer eliminated the need for a $25,000 custom welding fixture thanks to our use of the FabriGear and its ability to optimize fitup for assembly.”

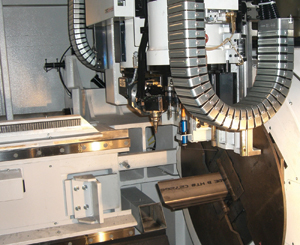

The laser system (shown in the photo preparing to cut a length of 4- by 2-in. tube) automatically loads and unloads workpieces, and reduces assembly steps with its ability to perform multiple tasks in one pass. “In a single operation that takes just minutes,” says Corey, “the FabriGear can cut a tube or beam (to 11.8-in. OD) to length, provide beveled edges, cut and tap holes and more. Its automated processing provides far greater precision, speed and quality than a three-step manual process of drilling, cutting and beveling. For example, the system takes only 80 min. to complete one structure that previously required 6 hr. to complete using three separate operations.”

Pickwick has developed applications for the FabriGear in environmental, wind-energy, agricultural and other industries. “We have begun collaborating with our clients to develop methods to eliminate fixtures and tack welding, saving them even more costs and time in fitup and assembly,” Corey adds.

Mazak Optonics: 847/252-4500; www.mazaklaser.com

See also: Mazak Optonics Corporation

Technologies: Cutting