Trimline Takes Delivery of Dallas Industries Feed Line

January 23, 2024Comments

Dallas Industries, Troy, MI, has delivered a conventional coil-feed line to TrimLine, LaGrange, OH, a division of Varbros, LLC. The firm designs and fabricates precision tooling for the metal stamping industry and operates mechanical and servo presses from 200 to 700 tons with servo-transfer systems. Its new Dallas line features a pull-off coil reel with load car and coil guide rolls, peeler/threader/end debender with coil restrictor, a powered straightener, threading table and cabinet-mounted servo feed. It’s rated for coils to 30,000 lb. of 36-in.-wide material.

Dallas Industries, Troy, MI, has delivered a conventional coil-feed line to TrimLine, LaGrange, OH, a division of Varbros, LLC. The firm designs and fabricates precision tooling for the metal stamping industry and operates mechanical and servo presses from 200 to 700 tons with servo-transfer systems. Its new Dallas line features a pull-off coil reel with load car and coil guide rolls, peeler/threader/end debender with coil restrictor, a powered straightener, threading table and cabinet-mounted servo feed. It’s rated for coils to 30,000 lb. of 36-in.-wide material.

The line incorporates several automated setup axes, termed “Autoset,” to enhance job-setup speed and repeatability. The automated axes include feeder passline height and edge guides, straightener breaker rolls and edge guides, uncoiler coil guide rolls (for auto coil centering) and an automatically adjusting drag brake (based on coil O.D.).

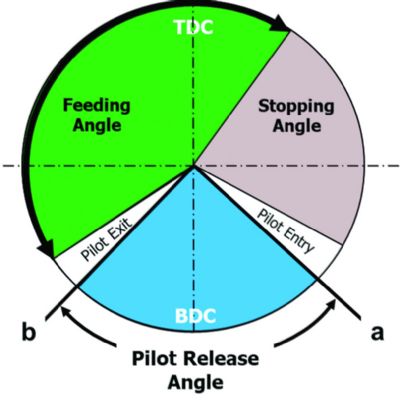

Also included: Allen-Bradley controls with SyncLoop and ProfileSelect. SyncLoop technology monitors average line speed and loop depth and adjusts payout speed automatically to ensure a smooth payout. The ProfileSelect feed control employs a sinusoidal (cam-motion) profile that results in a smooth feed motion utilizing 100% of the press-feed window, reducing stress on the material and the feed’s mechanical components.

See also: Dallas Industries

Technologies: Coil and Sheet Handling