“Generally, electrical fields look through all of that, paying no attention to the grease, oil or light,” he continues. The need to sense only an electrical field can make such technology more failsafe.”

Detection sensors can be placed anywhere in a line, given enough room.

“Most of our equipment resides at the beginning of a press line as automation that employs end-of-arm tooling (EOAT),” Vance explains, describing common setups. “The EOAT, using suction cups, picks blanks from a material stack to place into a die or onto a conveyor. This is the ideal location, right at the beginning of a process as a first line of defense to protect equipment and tooling.”

A variety of sensor setups exist for actual detection, including single-probe eddy-current systems—ideal in destacking and pick-and-place applications for materials where quick pickups and drops are paramount.

“Here, suction cups come down and contact the part, with an electromagnetic signal probe activated and deactivated via a pulse to pick up and then release a sheet as needed,” says Vance.

Technology allows for double-sheet detection across a wide swath of material thicknesses. For its part, Prime Controls offers solutions for material as thin as the foil on blister packs or on top of orange-juice containers, to blanks 0.25 in. thick. By using stronger magnets and various probes, thicker materials become candidates for double-sheet detection, according to Vance.

In deciding on a proper system, metal formers should be prepared for questions from potential suppliers.

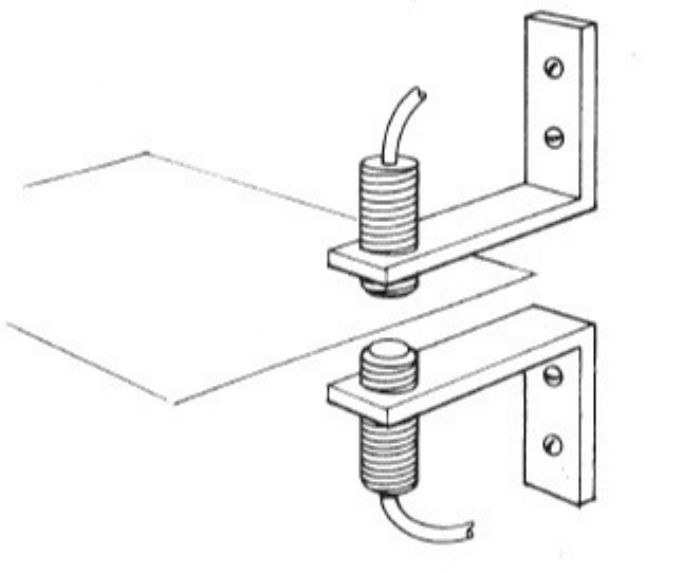

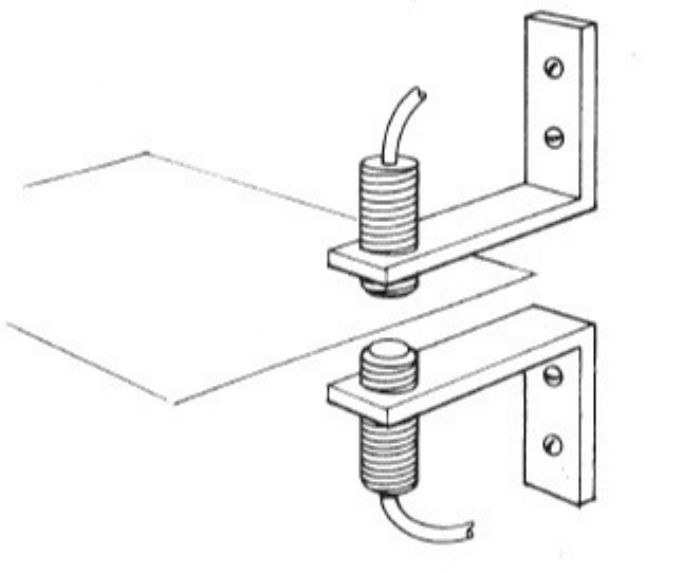

“Typically, we want to know the material type—ferrous or nonferrous—and the range of thicknesses to be run on a particular line,” Vance says. “We also ask if a metal former prefers a probe to contact the material, or if material should pass between a transmitter and receiver in a noncontact dual-probe setup (Figs. 2 and 3), often employed when producing parts with Class A surface finishes. From there, we can recommend an ideal system. Metal formers have a lot of flexibility when looking to home in on the most effective method of double-sheet detection for their needs.”

“Typically, we want to know the material type—ferrous or nonferrous—and the range of thicknesses to be run on a particular line,” Vance says. “We also ask if a metal former prefers a probe to contact the material, or if material should pass between a transmitter and receiver in a noncontact dual-probe setup (Figs. 2 and 3), often employed when producing parts with Class A surface finishes. From there, we can recommend an ideal system. Metal formers have a lot of flexibility when looking to home in on the most effective method of double-sheet detection for their needs.”

Working with precoated or prelubed ferrous material presents no challenges for a double-sheet detection system that employs electromagnetic sensing rather than vision systems.

“The sensors ignore coatings or lubricants,” says Vance. “They’re just looking for the presence of ferrous metal. A coating may affect a laser system, and a bright material finish hampers the effectiveness of cameras.”

Tackling Line Speed and Integration

In general, a solid detection system will have no problem keeping up with stamping-line speeds, as the technology provides rapid response times.

“Speed is not a limiting factor,” Vance says. “For our part, we derived our detection systems primarily from experience in canmaking applications. Canmaking machinery stamps out perhaps 1000 can tops/min., and the eddy-current-based technology typically offers a response time of 5 msec. The technology keeps up with canmaking, which is well beyond line speeds in general and automotive stamping, or in transfer applications.”

Double-sheet detection systems can operate independently or in concert with other line components.

“Control setups are available at various levels,” Vance says.

Basic setups may include discreet output via the PLC to provide a signal of a good condition or a double sheet, and expand from there.

“For example, suppliers enable different forms of industrial communications―such as Ethernet, Modbus, RS232, etc.―to connect the PLC to the press and tie in for automatic shutdown should a double sheet be detected,” says Vance. “The system’s controller enables users to prescribe a specific time frame for detecting a double-sheet condition or store job settings in memory.”

Beyond system cost, the ability to integrate double-sheet detection into a stamping line represents the biggest concern for stampers.

“Potential users want to know where the system can fit, and where the probes and controllers will reside,” Vance says. “Given the variety of blank-feed and material-transfer equipment, each stamper may have unique setups with limited available space for sensor placement.”

A system supplier should offer a variety of sensor sizes to fit any line size. For example, Prime Controls can specify barrel sensors in a variety of sizes as well as 2 by 3-in. block sensors for dual-probe applications, such as in transfer-press lines where transfer tooling picks and drops parts at various forming stations, according to Vance.

“Most difficult is finding the correct locations for dual-sensor probes, due to the limited distances (about 3 in. max) in which the probes can be separated from each other,” he explains. “A tight sensing area enables concentration on the material to be detected, whereas extended sensing areas introduce the possibility of interference and unwanted detection.”

Overall, says Vance, “double-blank-detection systems are smart investments and easy to employ and use, with ours in particular offering simple pushbutton setup.”

At the end of the day, such systems can deliver much-needed peace of mind. MF

Industry-Related Terms: Alloys,

Blank,

Die,

Ferrous,

Forming,

LASER,

Lines,

Run,

Surface,

Thickness,

Transfer,

FormingView Glossary of Metalforming Terms

See also: Prime Controls, Inc.

Technologies: Coil and Sheet Handling

Let Brett Vance, business development manager of general metal forming industries for Prime Controls, Kettering, OH, explain. His company provides technology for detecting double blanks, and he knows why the ability to detect such mishaps provides comfort.

Let Brett Vance, business development manager of general metal forming industries for Prime Controls, Kettering, OH, explain. His company provides technology for detecting double blanks, and he knows why the ability to detect such mishaps provides comfort. “For example, we employ eddy-current technology in single-probe systems, and dual-probe systems use an electrical field to generate a thickness reading,” Vance explains. “That information routes back to a double-sheet or single-sheet signal to a controller.”

“For example, we employ eddy-current technology in single-probe systems, and dual-probe systems use an electrical field to generate a thickness reading,” Vance explains. “That information routes back to a double-sheet or single-sheet signal to a controller.”

“Typically, we want to know the material type—ferrous or nonferrous—and the range of thicknesses to be run on a particular line,” Vance says. “We also ask if a metal former prefers a probe to contact the material, or if material should pass between a transmitter and receiver in a noncontact dual-probe setup (Figs. 2 and 3), often employed when producing parts with Class A surface finishes. From there, we can recommend an ideal system. Metal formers have a lot of flexibility when looking to home in on the most effective method of double-sheet detection for their needs.”

“Typically, we want to know the material type—ferrous or nonferrous—and the range of thicknesses to be run on a particular line,” Vance says. “We also ask if a metal former prefers a probe to contact the material, or if material should pass between a transmitter and receiver in a noncontact dual-probe setup (Figs. 2 and 3), often employed when producing parts with Class A surface finishes. From there, we can recommend an ideal system. Metal formers have a lot of flexibility when looking to home in on the most effective method of double-sheet detection for their needs.”