Flattening, Straightening and Leveling

January 1, 2010Comments

Question: There seems to be some confusion, not to mention vigorous debate, within our company regarding coil-straightening equipment. I have two questions that I hope you can answer. First, is there any difference between a coil flattener and a coil straightener, or are they just two different s of saying the same thing? My second question concerns levelers. A coworker claims levelers are basically straighteners with back-up rollers that provide additional support behind the straightening rolls. I know that levelers and straighteners are different but I can’t explain how they differ. Can you explain the difference to me?

A: Without a doubt, one of the most frustrating experiences we encounter in the metal-stamping industry is trying to find common terminology that is used consistently and understood broadly. Technical terms like flattening, straightening and leveling are good examples. These terms can be used so loosely that they eventually become interchangeable. When this happens it is difficult to know if there is any real difference in their meanings. This creates significant communication problems for all of us.

Flattening, straightening and leveling are terms commonly used to describe various coil-straightening methods. Coil straightening is accomplished by bending and unbending the incoming coil strip around several sets of rolls. The rolls alternately stretch and compress the upper and lower surfaces of the sheetmetal past its yield point until both surfaces have the same surface length. Technically speaking, this process is correcting surface-to-surface length differentials within the coil strip.

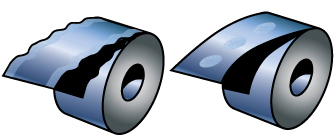

Fig. 1—Coil Set and Cross Bow

Surface-to-surface differentials include coil set and crossbow. Coil set occurs when the steel sheet is coiled. The inside surface of the sheet compresses during winding while the outside surface is placed in tension, causing it to stretch slightly. As a result, the inside of the sheet ends up shorter than the outside but it is consistent across the width of the coil. Cross bow occurs when the bottom side of the material is shorter than the top side when measured across the width of the coil. This condition is usually induced during coil slitting. Fig.1 illustrates both conditions.

The number of rolls in a straightening device correlates to the number of yielding strains (bends) it can produce. his in turn determines the extent of possible coil correction.

The most common coil-straightening devices found in the press shop are spread-center straighteners. These straighteners usually have five or seven working rolls capable of producing three to four yielding strains. These devices are recognizable by their large roll diameters and relatively wide spacing. They can remove coil set only, and often are referred to as “flatteners.” Flatteners can satisfy the requirements for most mild steel and some HSLA applications. For the most part, these widely spaced straightener rolls are not backed up.

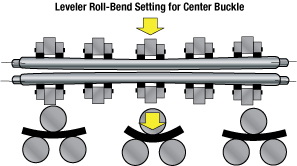

Close-center straighteners can have as few as nine working rolls and as many as 21 or more. The rolls are spaced much closer together as compared to flatteners and usually are backed up with additional supporting rollers. These straighteners can induce at least four yielding strains, which give them the added ability to correct cross-bow problems.