Coldwater Machine Designs and Ships Flexible HVAC-Fabrication Line

May 19, 2020Comments

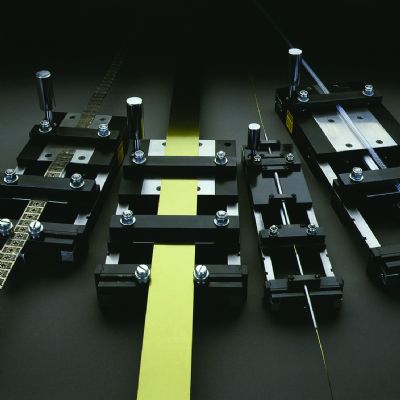

Coldwater Machine Co., Coldwater, OH, a Lincoln Electric Company, recently shipped a flexible wrapper and control-panel fabrication line to Texas for the fabrication of 14 different sizes of air-conditioning units. Based upon customer specifications, Coldwater coordinated the coil-processing equipment, mechanical press and tooling suppliers, and the supply of quick-die-change, post-mechanical press operations and the line’s master controls.

Coldwater Machine Co., Coldwater, OH, a Lincoln Electric Company, recently shipped a flexible wrapper and control-panel fabrication line to Texas for the fabrication of 14 different sizes of air-conditioning units. Based upon customer specifications, Coldwater coordinated the coil-processing equipment, mechanical press and tooling suppliers, and the supply of quick-die-change, post-mechanical press operations and the line’s master controls.The process begins with feeding of the coil stock—0.029-in. cold-rolled steel--to a 400-ton mechanical press, featuring two automated gag dies that transition to accommodate different-sized panels. The coil feeds into the press in variable increments for stamping of louvers.

After stamping, the material indexes out of the press for shearing, and then transfers to a bead and toggle station, comprised of two side-by-side 40-ton servo-hydraulic presses. Material then routes to a final form station, which also features two 40-ton hydraulic presses for bending the panels. A robot then reaches in to remove the parts and place them onto a conveyor.

See also: Lincoln Electric Automation

Technologies: Coil and Sheet Handling, Pressroom Automation, Stamping Presses

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Coil and Sheet Handling

Coil and Sheet HandlingDallas Industries Delivers Feed Line to ODM Tool & Manufactu...

Wednesday, July 9, 2025

Coil and Sheet Handling

Coil and Sheet HandlingPress Feed Strong

Kate Bachman Wednesday, April 23, 2025

Coil and Sheet Handling

Coil and Sheet Handling5 Questions About Air Feeds; 5 About Servo Feeds

Bradley Nordlof Thursday, April 17, 2025