Automatic Feed’s Upgraded Drives and Controls Produce Energy Savings

May 13, 2020Comments

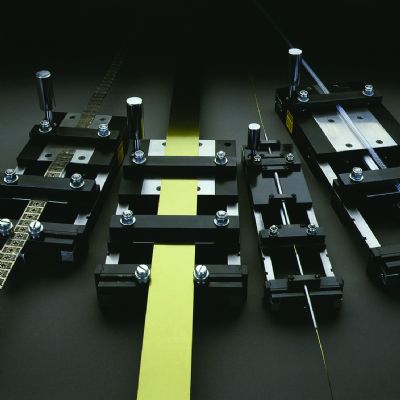

Automatic Feed Company (AFCO), Napoleon, OH, has upgraded the drives and controls used on its coil-processing equipment, reportedly resulting in increased production output and reduced energy usage and costs. According to company officials, one customer’s recent switch from DC to AC drives on its cut-to-length line and stacking equipment resulted in a 76-percent reduction in power consumption.

Automatic Feed Company (AFCO), Napoleon, OH, has upgraded the drives and controls used on its coil-processing equipment, reportedly resulting in increased production output and reduced energy usage and costs. According to company officials, one customer’s recent switch from DC to AC drives on its cut-to-length line and stacking equipment resulted in a 76-percent reduction in power consumption.DC drives consistently use power inefficiently, even when a press feed line is idle and not in production. Through its data collection capabilities, AFCO can demonstrate the potential for energy savings, and the efficiency of its current power supply, prior to investing in an upgrade. This allows it to demonstrate power fluctuations, spikes and dips, all of which can affect equipment performance.

Along with direct cost savings from reduced power consumption of the upgraded equipment, metal formers also can gain power efficiencies and lower demand for total incoming power. This newly available power capacity enables metal formers to increase production without having to invest in additional equipment.

See also: Automatic Feed Company

Technologies: Coil and Sheet Handling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Coil and Sheet Handling

Coil and Sheet HandlingDallas Industries Delivers Feed Line to ODM Tool & Manufactu...

Wednesday, July 9, 2025

Coil and Sheet Handling

Coil and Sheet HandlingPress Feed Strong

Kate Bachman Wednesday, April 23, 2025

Coil and Sheet Handling

Coil and Sheet Handling5 Questions About Air Feeds; 5 About Servo Feeds

Bradley Nordlof Thursday, April 17, 2025