Punching Their Way to Greater Productivity

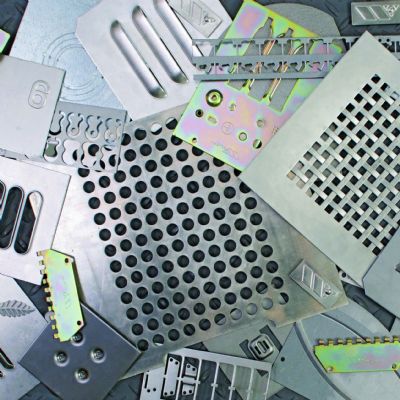

November 1, 2019 Two metal formers--one a Midwest fabricator and the other a Canadian manufacturer of fire-equipment enclosures--increase punch-press productivity with tooling solutions.

|

| This radius tool, designed for punch presses with auto-index stations, produces large holes using far fewer hits than a nibbling punch. |

A little innovation goes a long way in replacing repetitive manufacturing processes and secondary operations. A Midwest-based fabrication shop found that to be true when it discovered an alternative to its use of nibbling, the practice of producing large holes using a small punch that makes a series of overlapping hits. For a Canadian manufacturer of fire-hose and extinguisher cabinets, innovation came in the form of finding a way to eliminate its need for a three-piece spot welded assembly.No More Nibbling

While nibbling works, says Gary Troxell, sales engineer at Mate Precision Tooling, it requires many strikes to achieve the necessary holes. For the fabrication shop, this resulted in 90 sec. to nibble each part, which the company considered a problem.

The solution? A quad-radius tool and auto-index station that enables 8-, 12-, 16- and 20-in.-dia. punches in a 2-in. station, saving 30 sec. per part. With this fabricator producing 2000 parts/month, it saved 1000 min. (16.7 hr). At a labor rate of $45/hr., the customer saved $750/month or $9000/yr.

|

| This SnapLock lance-and-form tool produces self-locking, spring-loaded tabs that snap securely into pre-punched holes, eliminating the need for welding or additional assembly operations. |

Another and perhaps more important way to look at the 16.7 hr. saved: “The company gained 16.7 hr./month of production time, or 200 annual billable hours,” says Troxell. “At a billable shop time of $125/hr., there’s potential to increase annual billing by $25,000.”No More Spot Welding

Toronto, Ontario-based Williams Brothers discovered that it could eliminate secondary spot-welding operations when manufacturing fire-equipment cabinets. Working with Peter Visser, sales engineer at Mate, the OEM employed a SnapLock lance-and-form tool that produces self-locking, spring-loaded tabs that snap securely into prepunched holes, forming a mechanical lock and eliminating the need for welding. This involved learning how to set up the press brake to achieve consistent bends to ensure that the parts snap and lock together.

Materials

Materials CNC Punching

CNC Punching CNC Punching

CNC Punching