CNC Punching—Mind the Basics

March 1, 2017Comments

It's no secret that automated punching can be tricky business. But following some simple procedures and using the correct tools for the application will not only yield the quality parts you seek, but also deliver high tool mileage.

From drive technology to automation, CNC punching machines have undergone a sea change of innovation and improvement, making them an indispensable high-tech staple of any successful fabricating operation. But given the whiz-bang nature of today’s punching equipment, tried-and-true punching basics still hold true. The following tips and tricks help ensure that your CNC-punch tooling will perform desired tasks across a long tool life.

Support Narrow Punches

|

| When blanking, use only sharp punches and dies, which increases the straight or burnished portion of the blank to provide straighter walls on required parts. |

Punches narrower than the material thickness are vulnerable to lateral forces that can bend and break the tool tip. A bent punch results in tight punch-to-die clearance on the side toward which the punch is bending, and the punch will dull quickly. In some cases, the punch can bend far enough to shave the die, damaging both tools. With this in mind, it is recommended to never nibble a strip narrower than 2.5 times the material thickness.

Even during normal operation, narrow punches benefit from support at the punch tip. A fully guided assembly should provide such support with close stripper-to-punch clearance. Here, the stripper clamps material to the die during the working part of the stroke so that it can support the punch as closely to the tip as physically possible. Fully guided assemblies in applications using narrow punch widths result in consistent production and tool life lasting three times longer than without guiding.

Better Blanking

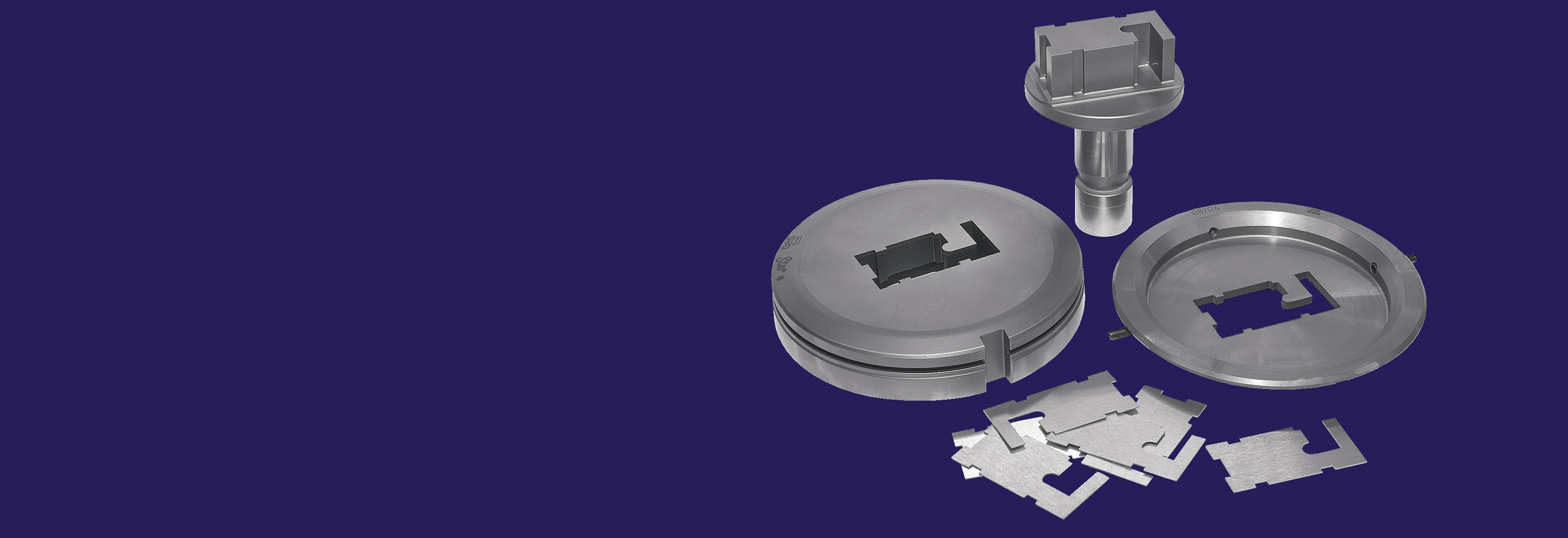

For high-quality blanks, where the slug, normally scrap, becomes the saved or good part, begin by determining critical blank dimensions and notify your tool manufacturer that the tools being ordered will be used for blanking. Remember, when blanking the die size is the blank size, so punch dimensions are calculated from the die dimensions. In addition:

-

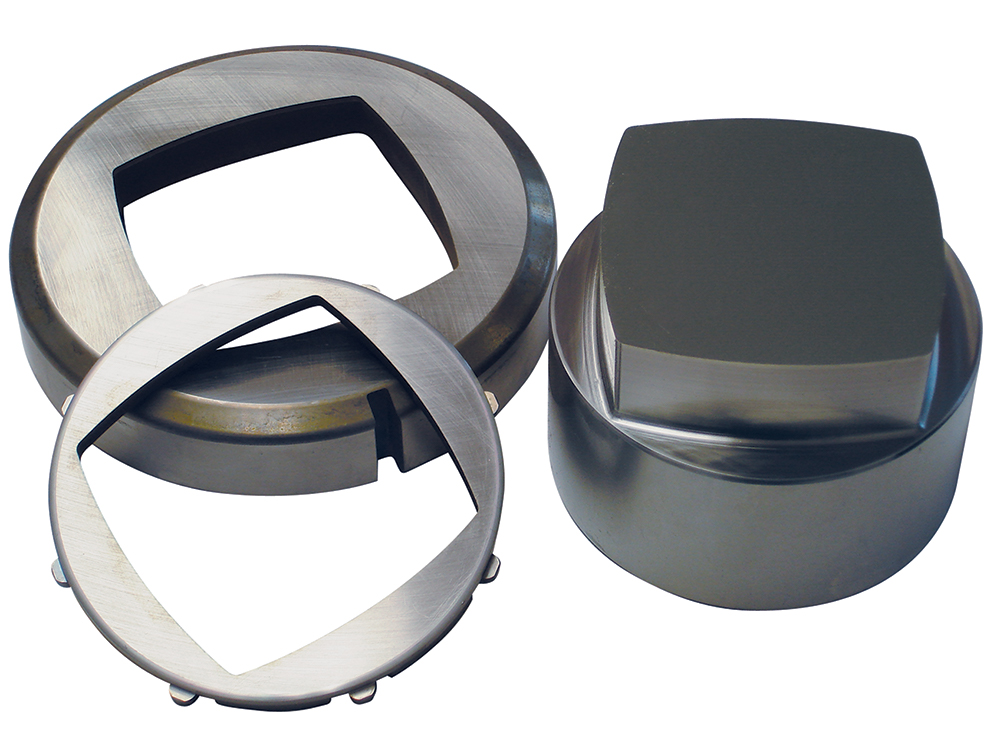

When specifying tools for blanking, notify your supplier of this fact. And remember, use nonslug-free dies and flat-faced punches. Use only sharp punches and dies. Doing so increases the straight or burnished portion of the blank to provide straighter walls on required parts.

- Reduce the die clearance by 5 percent. This helps to increase the burnish area and minimizes dimensional difference between the top and bottom of the blank.

- Punches should be flat-faced.

- Use non-slug-free dies.

- Inspect tools frequently for wear, as tools require sharpening more often when employing reduced die clearances.