Punch-Shear Comboa Labor Saver

December 1, 2016Comments

Shear and punch fabrication of sheetmetal parts at custom door manufacturer LaForce, Inc. more than triples thanks to implementation of a new servo-electric punch-shear combination machine.

|

| Improved accuracy and repeatability from the punch-shear combination machine has led to savings in downstream processes such as in press-brake forming, where dimensional accuracy from SGe enables faster setup times, and in welding due to improved part fitup. |

In 1954, Joe LaForce purchased a modest hardware-supply business in downtown Green Bay, WI. Today, his company, LaForce, Inc. has evolved into one of the largest U.S. distributors of commercial doors, frames, and hardware and building specialties. Its products can be found in a variety of office buildings, healthcare facilities, hospitals, nursing homes, clinics, schools, retail outlets and sports stadiums.

In addition to its Green Bay headquarters, LaForce operates 11 other U.S. locations, where it performs custom manufacturing of doors and frames, and offers product installation, pre-installation, pre-finishing, security integration, specification writing, fire-door inspections and key system services. Its 12 locations employ approximately 500 people.

|

Increasing Productivity, Improving Quality In addition to eliminating labor and improving dimensional tolerances, the punch-shear machine offers numerous features to enhance sheetmetal-fabrication productivity. These include: Tool-holder flexibility—Individual tool holders allow fabricators to design their own turret layouts, rather than having tool stations machined into the turret. Auto Index—The punch and die rotate in their tool holders, in 0.001-deg. programmable increments, and they can rotate beyond 360 deg., providing the shortest path to a programmed angle. Upward Forming—An upforming option provides accurate forming to 16 mm. And, all dies are at the same height, with minimal risk of material damage and increased machine uptime. |

In its early years, the company operated mostly as a distributor. By 1969, LaForce realized that he needed to bring door and frame production inhouse, in order to sell with consistent quality and make timely deliveries. Toward that end, the company purchased two turret punch presses, two hydraulic shears and several press brakes to fabricate and bend its products.

Fast forward to 2013, and LaForce began a search for a more efficient and productive way to fabricate its products at the 310,000-sq.-ft. headquarters facility.

“We used to shear the sheet to make blanks, and then punch the blanks into parts,” explains Brad Johnson, industrial engineer and continuous improvement coordinator. “We sought a way to avoid many of the wasted hours required for material handling and nonproductive labor.”

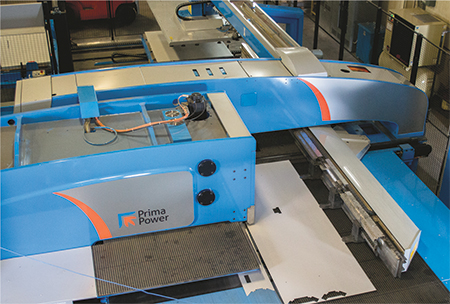

After much research, LaForce accomplished just that with the acquisition of a servo-electric punch-shear combination machine (a Prima Power Shear Genius SGe, acquired late in 2013).