The Trumpf-style tool has achieved a 0.984-in. overall feature height, with the thick-turret version approaching a 0.600-in. feature height, reports Erler—even higher when upforming.

“Again, if the tool had to travel above and beyond the form, these heights would be impossible to achieve due to lack of clearance,” she says.

Another advantage: the tool allows for a 3-deg. overbend to account for springback.

|

| For applications requiring hinges, CNC punching tools offer effective solutions without the need for secondary operations. |

“If the part requires a tolerance of ±1 deg., a traditional tool won’t suffice,” says Erler. “Sometimes a fabricator can cheat by using multiple hits, but often, meeting that tolerance is just not possible. Plus, due to the tool’s lower-unit cam, it provides a virtually mark-free form—beyond the typical capability of a traditional tool. Traditional tools usually leave marks due to the need to smack material fairly hard to reach and hold a 90-deg. angle.”This same tool can be used for multiple material gauges without pulling the sheet from the clamps, Erler reports.

Hinges

Several options exist for fabricating hinges directly in a punching machine.

“Electrical boxes, computer boxes ...any type of part with a door needs a hinge,” explains Erler. “Not only must a fabricator perform a secondary operation to install the hinge, but must buy the hinge itself. But, by manufacturing the whole box in a punching machine, instead of using that secondary operation to weld or rivet a hinge, the hinge can be created in the machine.”

Erler offers some options for creating the hinge.

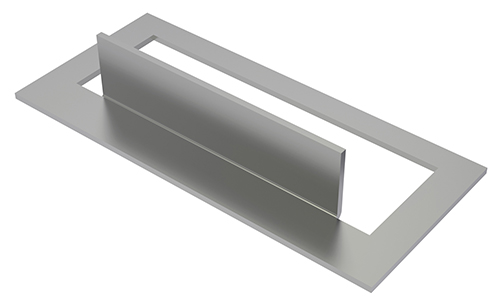

“A fully enclosed hinge requires two tools: a progressive-hit operation using the first tool that wipes the material with, typically, two or three hits, then the use of a second rollover tool that curls it over,” she says. “To maximize diameter and material thickness for that hinge, Wilson Tool offers the Opti-Bend as the first tool.

“A punching machine also can create a half-knuckle hinge, aka a one-hit hinge,” Erler continues. “One stroke can form multiple knuckles—a more efficient process than creating a fully enclosed hinge. This provides a good choice for applications requiring larger-diameter pins. Again, either method eliminates the need for expensive hardware and reduces assembly time, enabling fabrication of complete panels in the machine.”

Larger, Higher Embosses Minus Distortion

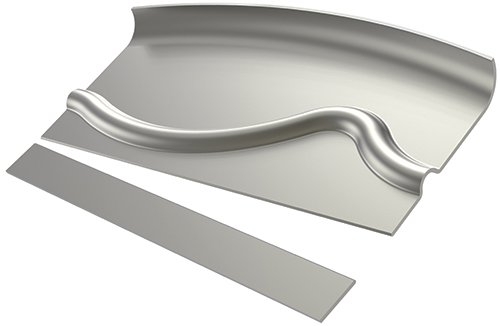

Given the right tooling, large, high, distortion-free embosses can be accomplished via a punching machine.

|

| A thread-form tool produces an offset emboss with a hole, enabling a self-tapping screw to sit flush with or below the sheet. |

“Distortion presents a limiting factor in any turret application, whether sheet distortion from an emboss or blank distortion,” Erler explains. “A rolling tool works with the material’s natural inclination to stretch and move. Instead of just forming the entire emboss with one hit, the tool works with a circular motion along the grain of the material, stretching and forming a little bit at a time. That eliminates the distortion because the tool does not try to form all of the material at once. It takes advantage of the material’s natural inclination to stretch with each tool move.”

Large-Diameter Flares

Use a punching machine to create large-diameter flares via, again, rolling tools. These essentially glide along around a shape to create the form, allowing the forming of shapes much larger than the tool-station size, according to Erler.

“For example, the Wilson Wheel Rolling Flare tool creates a flare—anywhere on the sheet—via a horizontal rolling motion without leaving burrs or nibble marks,” she says. “Typically, the fabricator thinks that the largest possible form cannot be larger than the largest station or tool in the machine. Wheel tools get around that limitation to create the radiused form. Also, using a single rolling tool results in a much faster process—with higher feature quality—than nibbling, where an incremental move may be the length of material thickness or less. Programming out the nibbling most likely will reveal a prohibitive timeframe—nibbling eats up a lot of machine time.”

Threaded Holes in Thin Material

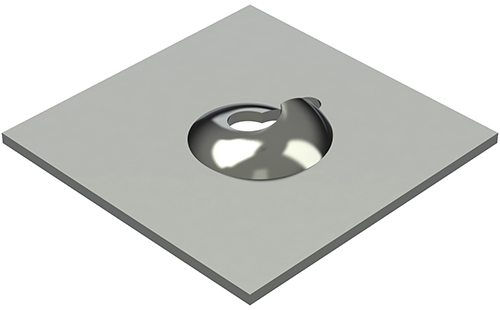

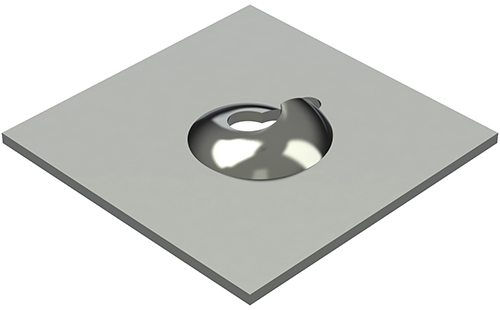

Thin material poses challenges should threaded holes be required, with additional hardware and secondary operations often needed. Thread-form tools employed in a punching machine provide an ideal alternative.

“A thread-form tool, with built-in coining capability, produces an offset emboss with a hole in it, either round or keyhole-shaped,” explains Erler. “A self-tapping screw threads that hole, with the screw head sitting flush with or below the sheet—typically the ideal fit. There’s no need for special hardware. Wilson Tool’s thread-form tool features a built-in coining operation to handle thicker material than what the thread size normally would call for. It’s one hit, followed by forming.”

Tapped Holes

Tapping holes within a punching machine eliminates a common secondary operation, and tapping can occur at any location on the sheet. And, tool capabilities enable rollformed tapping as opposed to cut threads. Rollformed tapping yields stronger threads with higher tensile strength, and because the threads are formed, not cut, tools produce no shavings.

“A quick-tap tool, depending on the thread size, locates either in the C or D station,” says Erler. “Users can thread either pierced or extruded holes, with extrusions upformed or downformed. Given perfect conditions, speeds approach 200 taps/min. The fastest manual operations just can’t compare. Also, punching machines can relocate directly over holes when tapping, which means high repeatability and high-quality threads.”

The List Goes On

Beyond what’s described here, fabricators can perform other operations in a punching machine that conventional wisdom routes to stamping presses, press brakes and standalone secondary operations. A discussion with machine and tool suppliers should provide enlightenment and help you win the efficiency game. MF

Industry-Related Terms: Turret Press,

Turret,

Tapping,

Tensile Strength,

Thickness,

Tolerance,

Forming,

Hardware,

Stroke,

Blank,

Cam,

Case,

CNC (Computer Numerical Control),

Coining,

FormView Glossary of Metalforming Terms

See also: Impax Tooling Solutions, A Div. of Wilson Tool International

Technologies: CNC Punching

Imagine a game show with various pieces of equipment on stage: a stamping press, press brake, numerous single-operation machines and a CNC punching machine. The show’s premise: Given a part feature, decide which piece of equipment can do the job. The host shouts out a feature:

Imagine a game show with various pieces of equipment on stage: a stamping press, press brake, numerous single-operation machines and a CNC punching machine. The show’s premise: Given a part feature, decide which piece of equipment can do the job. The host shouts out a feature: