Force Charts Explained

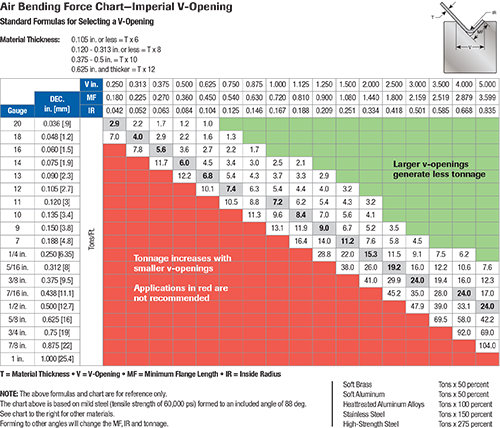

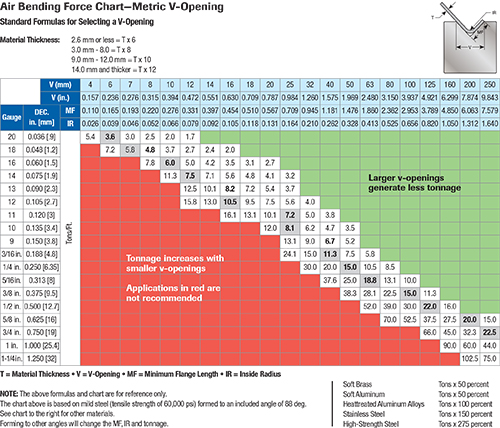

To assist in calculated needed tonnage for press-brake operations, we present the accompanying air-bending force charts. The charts supply an estimated tonnage for air bending a given thickness of mild steel in a given V-opening. The numbers in the white and gray boxes running diagonally from the top left corner to the bottom right corner of each chart denote the estimated tons/ft. required to perform a certain bend. If planning to bottom-bend or coin, use the charts to find the air-bending force required, and then multiply using the equations detailed above.

Important: The data in this chart is based on bending mild steel with a tensile strength of about 60,000 psi.

Start with the material to be formed as listed on the left and follow the row to the right until reaching the numbers. Notice that the tonnage numbers decrease from left to right, due to the fact that a larger V-opening requires less tonnage for that same material thickness. A shaded box represents the recommended V-opening for a particular material thickness. A red-shaded box indicates that the V-opening is too small for a given material thickness.

Tonnage limitations may dictate that a larger V-opening is required. But before jumping to a larger V-opening, consider how that will affect the form to be made. Will the larger V-opening accommodate the flange length or change the inside radius? Or, will a radius change in turn change the flat pattern or blank development?

Example 1: Bend 90 in. of 10-gauge mild steel with a 1-in. V

Follow the 10-gauge row in the Imperial V-Opening chart to the shaded box. The number is 8.4. This is the estimated tons/ft. required to form this application. Then follow that column straight up and notice that the V-opening is 1.125 in. But what if the machine only has a 1-in. V? Jump to the 1-in. column and follow it back down to the 10-gauge row. Notice that the tonnage number now is 9.6 tons/ft. This is still an acceptable tonnage to apply on the tooling, but does the brake have the capacity?

(90 in./12 = 7.5 ft.), 7.5 X 9.6 tons/ft. = 72 tons of total force required

Example 2: Bend 10 ft. of ¼-in.-thick stainless steel

Starting with the 0.250-in. row, follow it to the number in the shaded box, 15.3 tons/ft. (if a 2-in. V is used). But remember that this is stainless steel, which has a higher tensile and yield strength than mild steel. The factor for estimating this stronger stainless-steel material is 150 percent. (Remember that this is an estimate only—different grades of material will take more or less force, i.e., type 201 stainless steel may have different properties than a type 304.) So with the 150 factor included, we arrive at 15.3 x 1.5 = 23 tons/ft., and with 10 ft. to bend, the estimate is 230 total tons required.

Starting with the 0.250-in. row, follow it to the number in the shaded box, 15.3 tons/ft. (if a 2-in. V is used). But remember that this is stainless steel, which has a higher tensile and yield strength than mild steel. The factor for estimating this stronger stainless-steel material is 150 percent. (Remember that this is an estimate only—different grades of material will take more or less force, i.e., type 201 stainless steel may have different properties than a type 304.) So with the 150 factor included, we arrive at 15.3 x 1.5 = 23 tons/ft., and with 10 ft. to bend, the estimate is 230 total tons required.

In using these charts, keep in mind that it is not recommended to run at maximum capacity of the machine 100 percent of the time.

Don’t Forget About Springback

Remember that this chart is used for air bending and not for controlling the resulting inside radius. Tools must be able to accommodate springback should that be a concern with a particular material or application. In general, stainless steel and some aluminum grades require more overbend in order to achieve 90-deg. angles. A relatively large radius on the bend also will increase the amount of overbend required. If tooling is not acute enough to offer the needed overbend, more tonnage is the answer. Here, bottom bending may be an option, and bottom bending requires greater tonnage because the material is in full flat contact with sidewalls of the V-opening. MF

Article supplied by Wilson Tool International, White Bear Lake, MN; tel. 866/752-6531, www.wilsontool.com.

View Glossary of Metalforming Terms

See also: Impax Tooling Solutions, A Div. of Wilson Tool International

Technologies: Bending