Featured Content

CNC Punch Programming Efficiency

November 28, 2023 Comments

Quick, intuitive and smart automated functionality in programming software recently implemented at this 120-yr.-old sheet metal fabricator keeps the material moving through its lineup of CNC punching machines, lasers and press brakes.

YC Precision Fabrication established roots in York, PA, in 1902. Known then as York Corrugating Co., it manufactured gutters and corrugated roofing and siding. In 1917 YC established a metal stamping division and began to fabricate replacement fenders for the Ford Model T and for Indian motorcycles. Fast forward to today and we find the 121-yr.-old company operating a full-service metal-fabrication shop out of a 177,000-sq.-ft. facility outfitted with machinery for laser cutting, CNC punching, press brake bending, assembly and welding, and finishing.

We’re here to meet with the firm’s CNC laser/punch programming and SolidWorks designer Dustin Reeves, the man that toils behind the scenes to keep the orders moving efficiently through the production process. Reeves works tirelessly, starting early each morning preparing programs for a seemingly endless onslaught of incoming orders for customers in numerous industries, including military, heavy equipment and automotive, as well as for manufacturers of HVAC and commercial appliance equipment.

We’re here to meet with the firm’s CNC laser/punch programming and SolidWorks designer Dustin Reeves, the man that toils behind the scenes to keep the orders moving efficiently through the production process. Reeves works tirelessly, starting early each morning preparing programs for a seemingly endless onslaught of incoming orders for customers in numerous industries, including military, heavy equipment and automotive, as well as for manufacturers of HVAC and commercial appliance equipment.

Efficient Programming Catalyzes Shop Productivity

Reeves’ primary responsibility: Optimize efficiency of the firm’s sheet metal processing operations by quickly moving new jobs through programming functions on the front end. That means turning CAD files into nests for sheet metal blanks destined either for laser cutting or CNC punching operations, often followed by press brake bending.

The YC sheet metal shop features, among other equipment, two 10-kW fiber-laser cutting machines and a pair of CNC punching machines, both automated TruPunch models from Trumpf equipped to run lights out—which, says Reeves, the firm does nearly every day, sometimes for more than 10 hr. after first shift ends its workday. The two punching machines:

- TruPunch 5000, 24-ton punching capacity with 2500 by 1250-mm working range and 8-mm maximum workpiece thickness, equipped to handle 18 tools and three clamps, and able to drop parts as large as 80 by 50 mm through the chute.

- TruPunch 3000, 22-ton punching capacity and also for sheet to 2500 by 1250 mm and with 18-tool capacity, with sheet thickness capacity to 6.4 mm and maximum part size of 180-mm square for dropping through the chute.

“I often program jobs to run on both machines,” Reeves says, “to provide as much flexibility to the floor and to scheduling as possible.” He notes that the firm’s sweet spot in terms of material thickness ranges from very thin sheet to around 11 gauge.

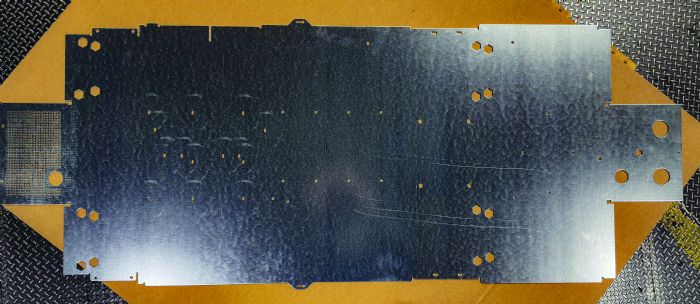

“We have one repeat job, for example,” Reeves explains, “that requires 143 sheets of material with seven parts nested per sheet. These are fan decks for tractor-trailers and the sheet nests include stiffening ribs. Each sheet takes 20 min. in the punching machine, so these jobs can run continuously for a couple of days.”

“We have one repeat job, for example,” Reeves explains, “that requires 143 sheets of material with seven parts nested per sheet. These are fan decks for tractor-trailers and the sheet nests include stiffening ribs. Each sheet takes 20 min. in the punching machine, so these jobs can run continuously for a couple of days.”