Large-Radius Bending on a Press Brake: Tackling Springback and Multi-Breakage

July 29, 2020Comments

Two challenges common to forming large-radius bends on a press brake include excessive springback and multi-breakage, with a new Mate Precision Tooling blog post explaining the challenges and how they can be met.

Two challenges common to forming large-radius bends on a press brake include excessive springback and multi-breakage, with a new Mate Precision Tooling blog post explaining the challenges and how they can be met.

Springback calculators provide a ballpark estimate of the final angle and radius, and Mate offers a wide selection of standard large-radius punch inserts in 25 radii sizes to ease achievement of the needed radius.

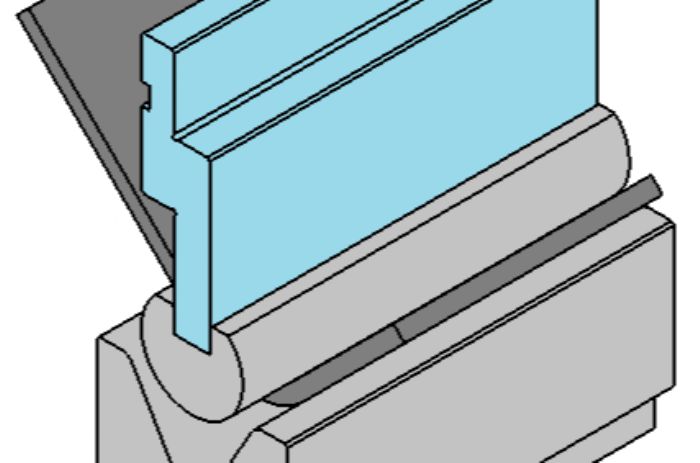

Multi-breakage occurs when the material lifts away from the punch during the bend. This results in a smaller final bend radius than the punch radius in the center of the bend. One solution to multi-breakage: providing counter pressure such as a urethane pad to keep the material in contact with the punch during the bend. Mate offers a variety of urethane pads and holders. Another solution: adding a flat tip to the large-radius punch. The flat tip creates a large contact surface between the punch and the work material.

See also: Mate Precision Tooling

Technologies: Bending

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Bending

BendingCreative Approaches to Common Press Brake Challenges, Part 4...

Justin Talianek April 25, 2025