Wabtec On Track to Reap Performance Gains from Metal AM

February 4, 2021Comments

Modernization and transformation lie at the heart of the railroad industry, as railroad operators and their suppliers have for the last several years worked hard to upgrade locomotive performance to meet new emission standards, reduce fuel consumption, improve reliability and increase cargo capacity. One highlight of the building momentum in this industry occurred in February 2019 when GE announced the spinoff and merger of its transportation business with Wabtec Corp. Wabtec president and CEO Raymond T. Betler said at the time that the deal represented “a once-in-a-lifetime opportunity to bring together nearly four centuries of collective experience to create a technologically advanced leader with a highly complementary set of capabilities to move and improve the world.”

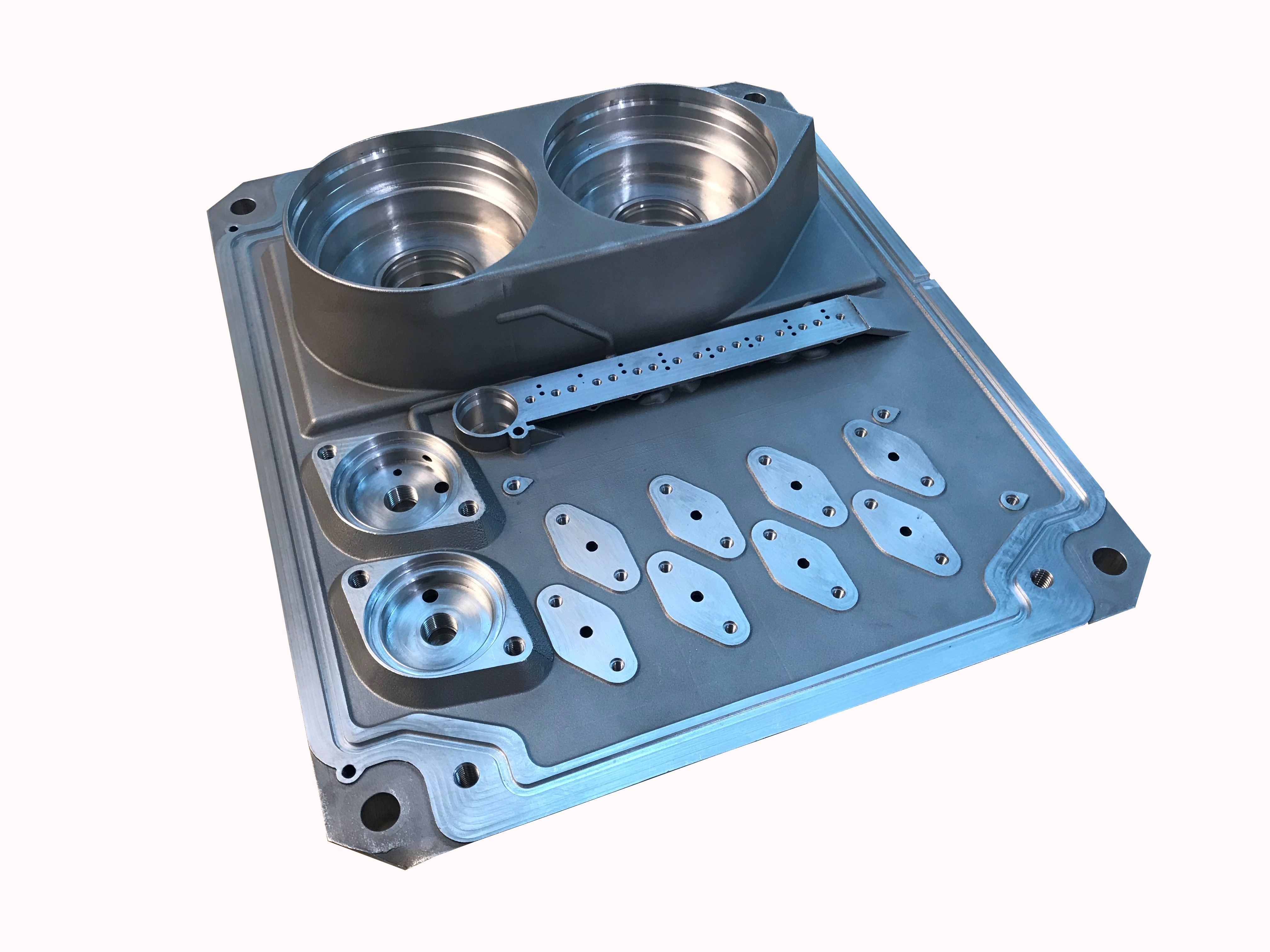

Of note to the AM industry: Wabtec executives call AM one of the technology pillars for its company. Its initial foray into metal AM, says Jennifer Coyne, AM leader at Wabtec and formerly senior systems engineer at GE Transportation, occurred in 2017. Then, efforts focused on prototype development using a laser-powder bed printer and, added in 2019, with a binder-jet machine for printing stainless steels. The AM team there, says Coyne, quickly identified some 250 components—for locomotives, heavy-haul vehicles and transit vehicles—where AM might fit. Throughout 2019, Wabtec reports that it had printed more than 800 production parts and more than 1250 prototype parts.

Of note to the AM industry: Wabtec executives call AM one of the technology pillars for its company. Its initial foray into metal AM, says Jennifer Coyne, AM leader at Wabtec and formerly senior systems engineer at GE Transportation, occurred in 2017. Then, efforts focused on prototype development using a laser-powder bed printer and, added in 2019, with a binder-jet machine for printing stainless steels. The AM team there, says Coyne, quickly identified some 250 components—for locomotives, heavy-haul vehicles and transit vehicles—where AM might fit. Throughout 2019, Wabtec reports that it had printed more than 800 production parts and more than 1250 prototype parts.Fast forward to 2021, when this spring Wabtec will open a new AM facility at the newly launched Pittsburgh Airport Innovation Campus. “We’ll use this new dedicated facility,” Coyne says, “to produce large-scale lightweight parts for transit and freight rail applications. Converting these parts to AM will reduce lead times as much as 80 percent.”

Wabtec officials reveal plans to use AM in the production of more than 25,000 parts by 2025.

Capitalizing on Build Height

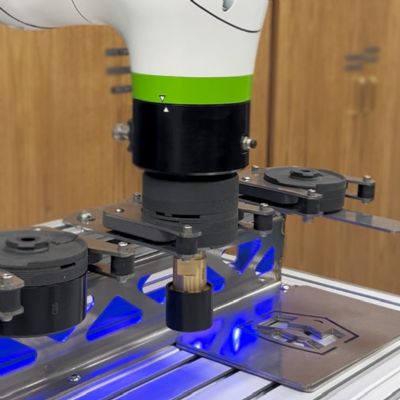

Wabtec is leasing more than 11,000 sq. ft. of space at Pittsburgh’s Neighborhood 91 195-acre dedicated AM campus. Neighborhood 91, developed in conjunction with the University of Pittsburgh, is a new hub connecting all aspects of the AM supply chain. Front and center at the new Wabtec AM space upon opening: an SLM 800 quad-laser powder-bed printer.

The SLM 800, which debuted at formnext 2017, has a large 500 by 280 by 850-mm build volume, including the build plate, and features four 700-W lasers. Particularly noteworthy is the 850 mm of build height to suit the relatively rapid building of large parts, with minimal supports, say company officials. They also point to the patented sintered-wall technology designed to keep the build chamber clear of soot and debris during the long and multiple-layer vertical builds. Waste material is neatly gathered and disposed of and clean gas returns to the build chamber.