Tooling Solutions Evolve to Keep Pace

To say that hot stamping taxes tooling is quite the understatement, and material providers as well as tool designers and builders are striving to meet the challenge.

“For hot stamping, we’ve seen an evolution of tool steel standard grades such as H13 and lower-alloyed steels, with all of that pushed upstream to higher-alloyed materials due to critical die expectations related to cycle time and wear,” says Hitachi Metals’ Bell.

Any material with yield strength surpassing 1200 MPa is considered for hot stamped parts, he notes, which truly stresses tooling. Tool-material providers are well aware of the challenges, and are working to meet the needs.

“The challenge in the tool steel business: meeting wear and toughness requirements simultaneously,” Bell says. “But meeting these properties makes the tool steel difficult to work with—more difficult to machine.”

Machining difficulty becomes extra challenging for hot stamping tooling, given the cooling channels and complex forms inherent in dies used in this process.

“The expanding requirements related to hot stamping keep us innovating,” Bell says.

He points to two technologies that have a role to play in tool material selection and die design/build for hot stamping: surface coatings and AM.

“As a steel maker, we want to make the best possible steel, meaning the best substrate and the best mechanical properties,” Bell says. “Surface coatings can help in terms of lubricity and wear, and we’re seeing development of coatings that can withstand hot stamping.”

As for AM, “3D printed inserts enable the creation of effective conformal cooling lines in hot stamping dies,” Bell says. “Traditionally, a water line in a hot stamping die runs along the X or Y axis—very linear. It doesn't always reach the surface of the die contour to cool as quickly as needed. AM inserts can be built to do that, which provides a big advantage.”

What remains to be seen, according to Bell, is whether AM technology can enable manufacture of inserts large enough to be effective in the very large hot stamping dies.

AM-Specific Tool Steel Boasts Simplified Printing

From production-line components to the manufacturing process itself, the metal forming industry continues to respond to the unique requirements of hot stamping and encourages the use of AM as a viable production option for mission-critical hot stamping tooling parts. As hot stamping is conducted on higher and higher strength steel materials, so, too, as Bell offers, must tool steel materials evolve to form such parts.

In his presentation at the Hot Stamping Experience and Tech Tour, Formetrix’s Lemke details the R&D and application development work involved, and his stated payoff: Easy-to-print powdered tool steels formulated specifically for the laser powder bed fusion process. The result: Conformally cooled tool designs offering benefits such as shorter tool lead times, lower hot stamping cycle times and hot stamping of more complex parts.

Recounting his lengthy forming-material experience, Lemke cites the ever-present efforts to drive 3D printing down the cost curve.

“Back in 2007,” he recalls, “I realized that except for maraging steel, which isn’t very common in the tool steel industry, no tool steels could be printed easily via laser based powder bed fusion, the most common metal AM process.”

Those tool steels that were printed, he notes, required preheating of the material to 750 F or higher, further increasing the 3D printing cost. Though no commercial metal printers existed at the time, Lemke was cognizant of what would be coming. As he explains, higher volumes of metal-powder production would drive down costs, and with AM reaching into higher-part-volume arenas such as automotive and industrial, an affordable AM steel powder with the needed hardness and toughness would be a boon to the industry, as was the case decades ago with sintered powdered metal.

Combining such material with the AM process delivers an alternative to long tooling lead times while enabling design freedom. This is especially important in hot stamping, Lemke says, which often requires intricate cooling channels. Efficiently designed tooling also offers the opportunity to reduce cycle times—another hot stamping challenge.

In his presentation, Lemke discusses the properties, applications and benefits of a crack-free AM powder, printable at room temperature and exhibiting high hardness and high ductility. He also discusses the postprocessing options such as heat treatments, carburizing, nitriding and PVD coating under tight dimensional control and given surface-roughness requirements.

In researching and testing formulations in the quest for such AM powder, “I don't know how many hundreds of pieces I have seen cracking,” Lemke says. “The insidious thing is, sometimes we would print it, go home and celebrate success. Then after a day or two we would see the cracks. These developments took years of work and came to a successful conclusion.”

Further, the presentation will include parameters and printing speeds on different machines as well as heat treatment results from commercial heat treaters in the United States and Germany, as well as an economic outlook. One end-use success to be detailed by Lemke at the event relates to a hot stamped production part for a 2019 North American truck.

Attend for More, Including a Tour

The Hot Stamping Experience and Tech Tour, a one-of-a-kind event, is designed to dive deeply into the ever expanding world of hot stamping. It features presentations from industry experts as well as a tour of host company Urgent Design & Manufacturing, Lapeer, MI, part of the 3-Dimensional Services Group. A Tier-One automotive supplier, 3-Dimensional Services Group provides vertical integrated rapid manufacturing services, including design, engineering and manufacturing of precision prototype parts and assemblies. In addition, it has invested significantly to modernize equipment to better support low-to-medium-volume production applications.

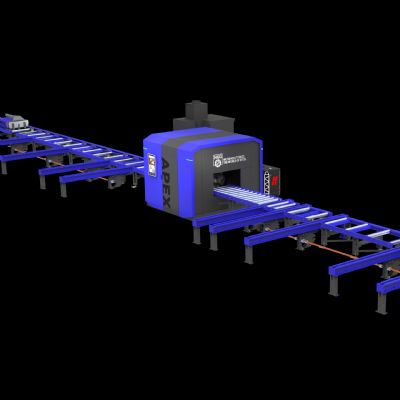

In Lapeer, 3-Dimensional Services houses its prototype and low-volume hot stamping capabilities, courtesy of Urgent Design & Manufacturing. This includes an automated hot stamping cell for prototyping. Trumpf three- and five-axis laser cutters trim blank material, and within the cell, two AP&T 500-ton, NC-controlled presses perform the forming, with a Kuka KR210 robot responsible for material transfer between the presses and furnace. The cell also provides automated material clamping. Hot Stamping Experience and Tour attendees will see how Urgent meets the needs of its OEM and Tier-One customer base via this cell and other capabilities.

Hot Stamping Experience and Tech Tour presentations include the following:

Novel, Cost-Efficient 3D Printed Hot and Cold Forming Tools for High Volume Part Production, by Harald Lemke, chief commercial officer, Formetrix. Learn about the benefits of 3D printing for the manufacture of tooling and dies, and for hot and cold forming, with novel designs and conformal cooling that extend tooling and die lifetime, and accelerate production.

Fundamentals and Applications of Hot Stamping Technology for Producing Automotive Parts, by Eren Billur, technical manager, Billur Metal Form Ltd. An introduction to hot stamping of UHSS technique and its evolution will be provided.

Welding Fasteners to Hot Stamped Coated Steels, by Bob Kollins, senior application engineer, Technical Sales & Solutions, and Allen M. Agin, Midwest regional sales manager, Weld Systems Integrators, Inc. Kollins and Agin will review the manufacturing issues encountered when projection welding fasteners onto hot stamped/press hardened, AlSi-coated components.

Laser Cutting Press Hardened Steel: Software and Hardware Advancements Combine to Reduce Cycle Time and Consumable Use, by Nathan Harris, industry management-automotive, Trumpf Inc. Learn how new laser cutting technology is helping shops working with press hardened steels meet the challenges presented by ever-increasing part sizes and pressure to maximize throughput.

Hot Stamping Die Development and Optimization, by Mike Austin, director–manufacturing engineering, Diversified Tooling Group. Learn more on the challenges involved and the options available when creating tooling for hot stamping applications.

Event details and to register. 3DMP

Industry-Related Terms: Bed,

Blank,

Carburizing,

Case,

Die,

Ductility,

Form,

Forming,

Hardware,

LASER,

Lines,

Nitriding,

Projection Welding,

Prototype,

Quenching,

Stroke,

Substrate,

Surface,

TransferView Glossary of Metalforming Terms

See also: Hitachi Metals America, Ltd., Formetrix Metals

Technologies:

Podcast

Podcast