New Supersonic Aircraft Features 21 Velo3D-Printed Ti Parts

October 8, 2020Comments

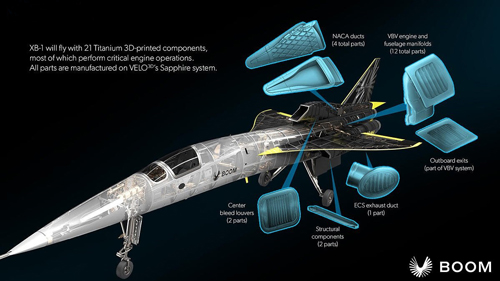

Velo3D announced that Boom Supersonic’s XB-1 aircraft, unveiled on October 7, includes 21 titanium flight-hardware components manufactured by Velo3D’s Sapphire 3D metal printer.

The printed parts are used for engine-hardware, environmental-control-system and structural components. Characteristics of the geometric designs include tall, thin walls with high aspect ratios, difficult to manufacture with traditional processes such as welding and casting, or even most existing 3D-printing technologies, according to Velo3D officials. Boom Supersonic and Velo3D announced a partnership in 2019 to manufacture complex flight hardware to build the XB-1, and ran a series of qualification trials on the Sapphire, leading to inclusion of the parts in this aircraft.

The printed parts are used for engine-hardware, environmental-control-system and structural components. Characteristics of the geometric designs include tall, thin walls with high aspect ratios, difficult to manufacture with traditional processes such as welding and casting, or even most existing 3D-printing technologies, according to Velo3D officials. Boom Supersonic and Velo3D announced a partnership in 2019 to manufacture complex flight hardware to build the XB-1, and ran a series of qualification trials on the Sapphire, leading to inclusion of the parts in this aircraft.

The XB-1 reportedly is the world’s first independently developed supersonic jet, and will be used to demonstrate critical technologies for Overture, Boom’s future commercial airliner, such as advanced carbon-fiber composite construction, computer-optimized high-efficiency aerodynamics and an efficient supersonic propulsion system.

See also: Velo3D

Technologies: