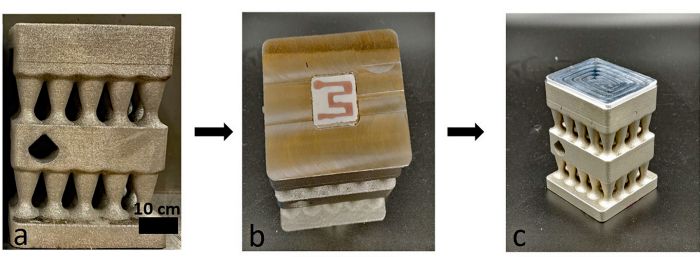

First, we employed laser powder-bed fusion (L-PBF) to build a bulk metallic component with a lattice structure and internal channels, for use as a base for the compounding AM processes (Fig. 1a). We designed the part to showcase specific design capabilities and highlight the structural benefits of building a part using L-PBF, and included overhangs, lattice support structures, and an internal cooling channel to showcase some of the types of geometries that L-PBF can create. And, we included some design changes to better suit the part for subsequent processes. For example, the design includes an indented slot for the RTD, since the top surface needed to be perfectly flat to accommodate the ultrasonic sheet-lamination AM process.

First, we employed laser powder-bed fusion (L-PBF) to build a bulk metallic component with a lattice structure and internal channels, for use as a base for the compounding AM processes (Fig. 1a). We designed the part to showcase specific design capabilities and highlight the structural benefits of building a part using L-PBF, and included overhangs, lattice support structures, and an internal cooling channel to showcase some of the types of geometries that L-PBF can create. And, we included some design changes to better suit the part for subsequent processes. For example, the design includes an indented slot for the RTD, since the top surface needed to be perfectly flat to accommodate the ultrasonic sheet-lamination AM process.

Minor design modifications were implemented after initial trial builds to improve overall printability and part quality. The component designs were used to prepare build files on EOSPrint 2.6, and the builds were made on EWI’s EOS M290 using Type 316L stainless-steel L-PBF-grade powder using EWI-developed process parameters for a 40-micron layer thickness.

Direct Ink Writing and Ultrasonic AM

Following L-PBF, we employed direct ink writing (DIW), a variant of aerosol jetting, to print a functional electrical RTD, for measuring temperature. We printed a copper-graphene nanocomposite ink onto a yttria-stabilized-zirconia (YSZ) substrate using a three-axis stage capable of controlling material feed and travel speed (Fig. 1b). This allowed deposition of a controlled amount of ink in a precise and easily customizable pattern. We selected a copper-graphene nanocomposite due to its positive temperature coefficient and incremental resistance increase with temperature—ideal for use as an RTD. The thin YSZ substrate and the customizable pattern and size make this type of sensor ideal for integration into a wide range of applications.

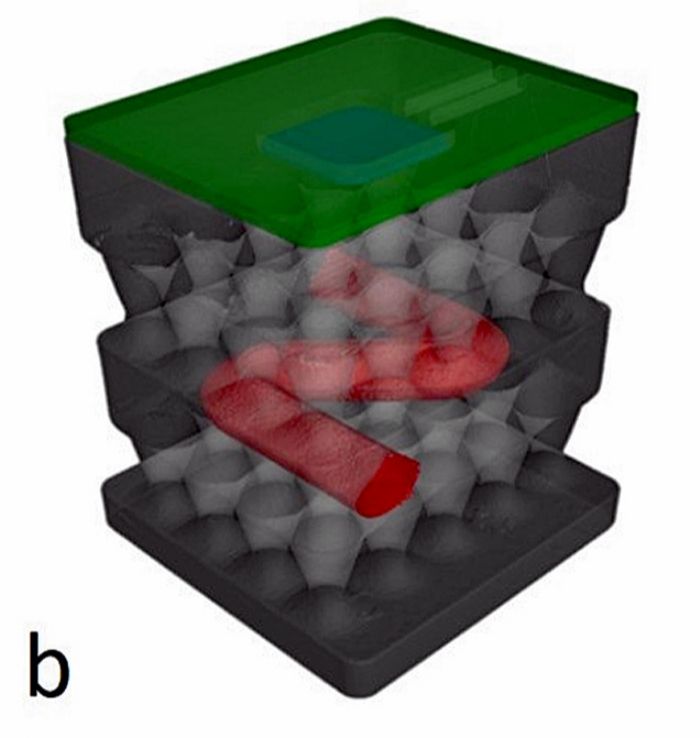

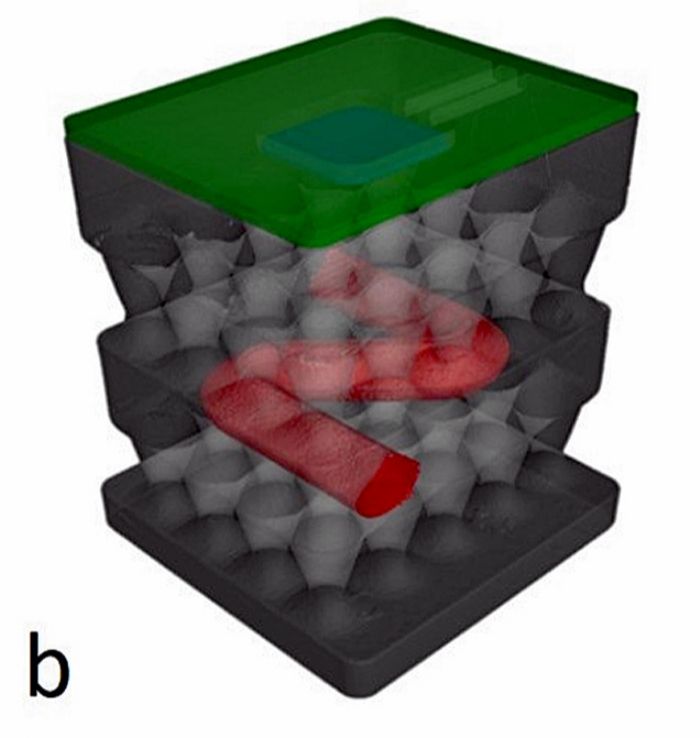

Next we used Fabrisonic’ s ultrasonic AM (UAM) process to encapsulate the RTD sensor into the top of the L-PBF component. Because UAM does not generate a lot of heat, it’s well-suited for AM on top of fragile melt-sensitive components such as electronics and sensors. Another unique characteristic: It can join dissimilar metals via solid-state bonding. In our case, we used the Fabrisonic hybrid UAM-CNC machining system to encapsulate the RTD in Type 6061 aluminum, laying down 154-um layers to achieve a 2.54-mm-thick cap (Fig. 1c).

Positive Results

The work resulted in the fabrication of several robust, multiprocess, multi-material hybrid AM components with embedded sensors. X-ray computed tomography revealed that the sensors were successfully embedded in the metallic component and remained intact (Fig. 2a). Upon further testing for high-temperature resistance, parts were placed in a box furnace and heated to 500 C, and the sensors survived the temperature cycling and provided accurate temperature measurements.

This success confirms the concept of multiprocess hybrid AM as a viable way to overcome manufacturing and SHM challenges in the hypersonic industry. These same techniques can be adapted for many other industrial applications involving different part geometries, sensors and materials. 3DMP

Note: This article was provided by Lee Kerwin from the EWI Buffalo Manufacturing Works location, and Ajay Krishnan from the EWI office in Columbus, OH.

Kerwin specializes in blown-powder laser directed-energy deposition and leads projects on EWI’s large-format additive systems. He also works as an expert in materials analysis, in-situ monitoring and precision metrology to evaluate part accuracy and integrity. Krishnan is an expert in laser powder-bed fusion and specializes in materials, processes, in-situ monitoring and applications engineering. As research leader, he also is involved in the technology strategy of the AM group and coordinates EWI’s AM R&D portfolio.

Financial support at University at Buffalo (S.R.) was provided by the U.S. Army Research Laboratory under Award W911NF-20-2-0016. Financial support at EWI was provided by the U.S. Army Research Laboratory under Cooperative Agreement W911NF-13-2-0038 (Modification P00011).

See also: EWI Materials Joining Technology, Fabrisonic LLC

Technologies:

Combining multiple AM processes to create a single component offers a way to expand manufacturing capabilities to overcome key challenges. Using several techniques together can enable the development of solutions to unforeseen problems and can deliver game-changing fabrication strategies by leveraging the inherent strengths of each AM process.

Combining multiple AM processes to create a single component offers a way to expand manufacturing capabilities to overcome key challenges. Using several techniques together can enable the development of solutions to unforeseen problems and can deliver game-changing fabrication strategies by leveraging the inherent strengths of each AM process.  This article presents a practical case study of how we at EWI leveraged multiple AM processes in sequence to enable SHM of a component via a resistance temperature detector (RTD) sensor. Working with Fabrisonic, we combined three AM processes with three different materials to embed an RTD sensor into a complex geometry only manufacturable using metal AM. This provides others with a possible approach to developing high-acceleration, high-temperature and high-vibration applications where more typical joining methods would not suffice.

This article presents a practical case study of how we at EWI leveraged multiple AM processes in sequence to enable SHM of a component via a resistance temperature detector (RTD) sensor. Working with Fabrisonic, we combined three AM processes with three different materials to embed an RTD sensor into a complex geometry only manufacturable using metal AM. This provides others with a possible approach to developing high-acceleration, high-temperature and high-vibration applications where more typical joining methods would not suffice.

First, we employed laser powder-bed fusion (L-PBF) to build a bulk metallic component with a lattice structure and internal channels, for use as a base for the compounding AM processes (Fig. 1a). We designed the part to showcase specific design capabilities and highlight the structural benefits of building a part using L-PBF, and included overhangs, lattice support structures, and an internal cooling channel to showcase some of the types of geometries that L-PBF can create. And, we included some design changes to better suit the part for subsequent processes. For example, the design includes an indented slot for the RTD, since the top surface needed to be perfectly flat to accommodate the ultrasonic sheet-lamination AM process.

First, we employed laser powder-bed fusion (L-PBF) to build a bulk metallic component with a lattice structure and internal channels, for use as a base for the compounding AM processes (Fig. 1a). We designed the part to showcase specific design capabilities and highlight the structural benefits of building a part using L-PBF, and included overhangs, lattice support structures, and an internal cooling channel to showcase some of the types of geometries that L-PBF can create. And, we included some design changes to better suit the part for subsequent processes. For example, the design includes an indented slot for the RTD, since the top surface needed to be perfectly flat to accommodate the ultrasonic sheet-lamination AM process.

Video

Video