Air Force Develops Steel for Additive Manufactured Parts

August 26, 2019Comments

|

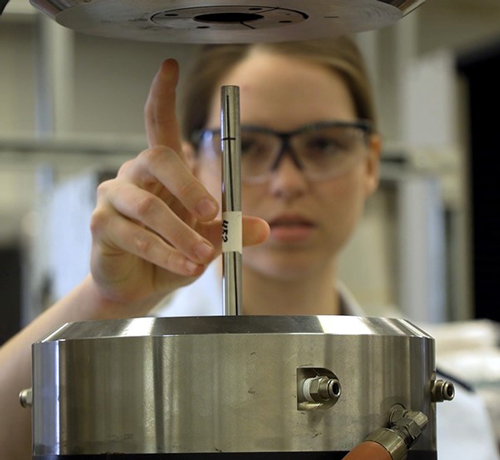

| After printing various parts with AF-9628 powder, U.S. Air Force Capt. Erin Hager analyzes the resulting porosity, strength and impact toughness.Air Force photograph. |

“To determine if AF-9628 was printable, we characterized the shape and size of the powder and how it changed with melting and sieving,” Hager says. She examined it under a scanning electron microscope at the Air Force Institute of Technology and performed tests at the University of Dayton Research Institute using a size characterizing light microscope.

Hager provided the chemical composition of AF-9628 steel to Powder Alloy Corp., a Cincinnati, OH-based powder provider. Once she received the powder and determined that it melted predictably in the machine, she moved on to creating actual test articles. After printing various parts, she analyzed the resulting porosity, strength and impact toughness and found no evidence of cracking, describing the output as “very similar to traditionally manufactured parts and that they met or exceeded [specifications] straight out of the machine.”

Hager used two machines at AFIT and printed about 130 articles, including 30 small cylinders, 60 larger cylinders, 20 tensile bars and 20 impact specimens. The parts made are suitable for weapons applications.

View Glossary of Metalforming Terms

Technologies: