SLM Solutions, Honeywell Team to Qualify Al Alloy for Thick-Walled Parts

July 20, 2020Comments

|

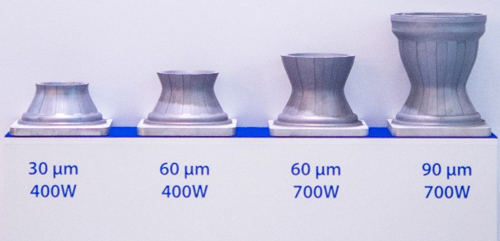

| As part of a development collaboration with SLM Solutions, Honeywell undertook qualification efforts for aluminum builds using increased layer thicknesses of 60 and 90 µm on a quad-laser SLM500 machine. The result: new parameter sets for aluminum alloy F357 using a layer thickness of 60 µm and 700-W lasers, reportedly yielding significantly increased material properties in comparison to conventional diecast parts, with these properties exceeding overall acknowledged metallic properties for aerospace. |

As part of the collaboration, Honeywell began qualification efforts for aluminum builds using increased layer thicknesses of 60 and 90 µm on a quad-laser SLM500 machine. SLM Solutions provided generic aluminum parameter sets for Honeywell to complete material qualification to achieve optimal material properties. The development of these new parameter sets for aluminum alloy F357 using a layer thickness of 60 µm and 700-W lasers reportedly has yielded significantly increased material properties in comparison to conventional diecast parts, with these properties exceeding overall acknowledged metallic properties for aerospace.

Besides its light weight, aluminum alloy F357 provides high corrosion resistance and desired mechanical properties such as high strength across a wide temperature range in comparison to conventional aluminum alloys. It offers excellent weldability and excellent suitability for post-processing, according to SLM solutions officials. The combination of properties makes F357 ideal for producing thin-walled and complex structures.

“The open architecture system of the SLM Solutions machine provides huge advantages such as high flexibility and parameter sets can be customized,” says Dr. Sören Wiener, senior director of technology and advanced operations at Honeywell Aerospace.View Glossary of Metalforming Terms

See also: SLM Solutions NA, Inc.

Technologies: Additive Manufacturing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Additive Manufacturing

Additive ManufacturingMeltio and Phillips Collaborate on Hybrid CNC Machining and ...

Monday, June 9, 2025

Additive Manufacturing

Additive ManufacturingAM for Tooling: Making Headway

Lou Kren Monday, March 3, 2025

Additive Manufacturing

Additive ManufacturingAM Event, RAPID + TCT 2025, Slated for Detroit in April

Friday, February 21, 2025