Research Funded to Benchmark Additive Manufacturing of Metals

March 1, 2014Comments

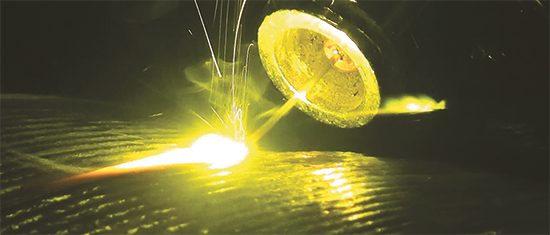

Lincoln Electric and Case Western Reserve University, Cleveland, OH, co-investigators developing a proprietary laser-assisted wire-based additive-manufacturing process for titanium- and nickel-based alloys, have received a second round of funding from America Makes (originally the National Additive Manufacturing Innovation Institute).

The research project, undertaken with partnering companies including AZZ/WSI, rp+m and RTI Intl., has focused on metal-cladding and layering to repair molds used in aluminum casting for the automotive industry. During round two, researchers will test and benchmark the process for generating structural parts with titanium alloys, and functional surfaces with nickel-based alloys.

Lincoln Electric: www.lincolnelectric.com

See also: Lincoln Electric Co.

Technologies: Additive Manufacturing