Autonomous Bin Picking Kit for Process Tending

April 13, 2020Comments

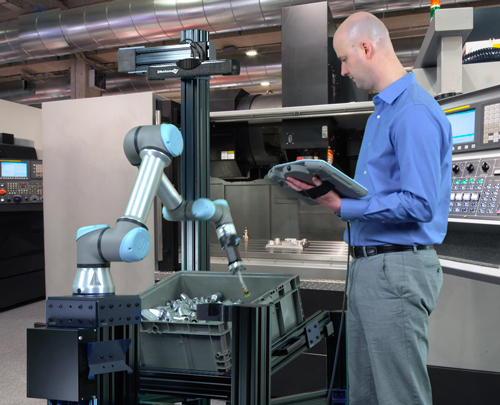

From Universal Robots (UR), ActiNav promises to simplify the integration of autonomous bin picking of parts and their accurate placement in machines and processes using the company’s collaborative robots (cobots). ActiNav synchronously handles vision processing, collision-free motion planning and autonomous real-time robot control, eliminating the complexity and risk usually associated with bin-picking applications.

Automated bin picking, traditionally a challenging process, requires significant integration and programming efforts, with most bin-picking products focused solely on the vision aspect of bin picking, according to UR officials, and often require hundreds of lines of additional programming to bridge the gap from pick to place, especially when placing goes beyond dropping into a box and involves accurate insertion of a part into a fixture for further processing. Conversely, ActiNav autonomous bin picking reportedly allows manufacturers to achieve high machine uptime and accurate part placement rapidly, with few operator interventions.

Automated bin picking, traditionally a challenging process, requires significant integration and programming efforts, with most bin-picking products focused solely on the vision aspect of bin picking, according to UR officials, and often require hundreds of lines of additional programming to bridge the gap from pick to place, especially when placing goes beyond dropping into a box and involves accurate insertion of a part into a fixture for further processing. Conversely, ActiNav autonomous bin picking reportedly allows manufacturers to achieve high machine uptime and accurate part placement rapidly, with few operator interventions.

ActiNav combines real-time autonomous motion control, collaborative robotics, and vision and sensor systems in a single kit, requiring no vision or robotic programming expertise It is based on a teach-by-demonstration principle using a six-step, wizard-guided setup process integrated into the UR cobot teach pendant, and can be deployed by manufacturers’ inhouse automation teams or through assistance from a UR distributor or integrator. Autonomous motion control enables ActiNav to operate inside deep bins that hold more parts; something that standalone bin-picking vision systems struggle to accomplish, according to UR officials.

ActiNav is available through UR’s distribution channel and via the new UR+ Application Kits platform, an ecosystem of components certified to work seamlessly with UR cobots. ActiNav works with UR’s UR5e and UR10e e-Series cobots, a UR+ component or user-defined end effector, and application-specific frame or fixture as needed. The kit includes the Autonomous Motion Module (AMM) and ActiNav URCap user-interface software, along with a choice of 3D sensors.

See also: Universal Robots

Technologies: Additive Manufacturing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Additive Manufacturing

Additive ManufacturingMeltio and Phillips Collaborate on Hybrid CNC Machining and ...

Monday, June 9, 2025

Additive Manufacturing

Additive ManufacturingUnited Performance Metals Acquires Fabrisonic

Monday, March 24, 2025