Airbus Adds EB Machine to Print Large Titanium Structural Parts

February 1, 2017Comments

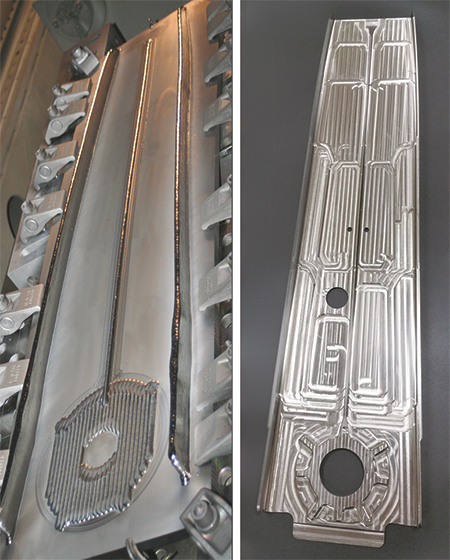

Sciaky, Inc., Chicago, IL, announced that Airbus planned to take delivery of an EBAM (electron-beam additive-manufacturing) 110 system (70- by 47- by 63-in. work envelope) in December 2016, to produce large titanium structural parts. Sciaky’s EBAM process combines computer-aided design, additive-manufacturing processing principles, and an electron-beam heat source. A fully-articulated, moving electron-beam gun deposits titanium via wire feedstock, layer by layer, until the part reaches near-net shape. From there, the part requires heattreatment and post-production machining.

Sciaky brings quality and control together in one step with its IRISS interlayer real-time imaging and sensing system, which can sense and digitally self-adjust deposition precisely and repeatably. This closed-loop control ensures consistent part geometry, mechanical properties, microstructure and composition.

Sciaky, Inc.: www.sciaky.com

See also: Sciaky Inc

Technologies: Additive Manufacturing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Additive Manufacturing

Additive ManufacturingMeltio and Phillips Collaborate on Hybrid CNC Machining and ...

Monday, June 9, 2025

Additive Manufacturing

Additive ManufacturingAM for Tooling: Making Headway

Lou Kren Monday, March 3, 2025

Additive Manufacturing

Additive ManufacturingAM Event, RAPID + TCT 2025, Slated for Detroit in April

Friday, February 21, 2025