Page 49 - MetalForming September 2017

P. 49

The Science of Forming

��������������� ��������������� ��� ��������� ��� ��������� ������������ ��� ������������������ ��� ��������������� ��� ������������ ��������� ��

���� ��� ������������������������

� ��

���

���

���

Wo

or

rkh

ho

oldi

ing

g C

Cl

la

a

am

mp

ps

+m

–m

σ=Κˊεm Strain ε

������ ��� ����� ����� ��������

����� ������������������ ����� ������� ������������

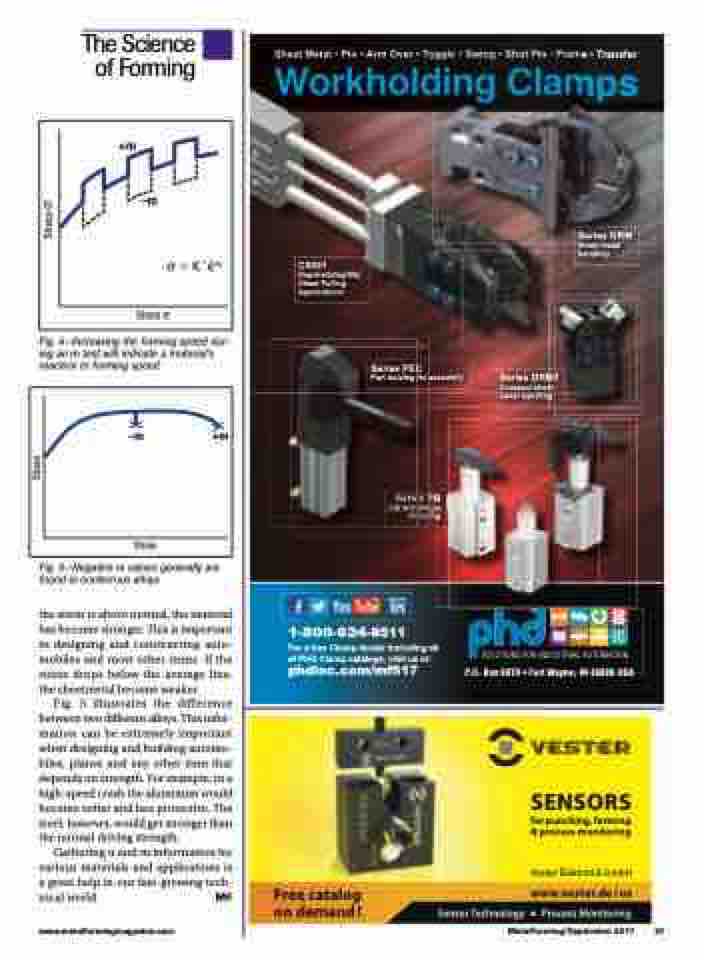

Fig. 4—Increasing the forming speed dur- ing an m test will indicate a material’s reaction to forming speed.

������ ���

���� ������� ��� ��������

������ ���� ������� ����� ����� ��������

X

–m +m

Strain

��������������

�

�

�� �

��������� ��������� ��

�����

���

���

����������

�������

���

���

�����������

Fig. 5—Negative m values generally are found in nonferrous alloys.

the stress is above normal, the material has become stronger. This is important in designing and constructing auto- mobiles and most other items. If the stress drops below the average line, the sheetmetal became weaker.

Fig. 5 illustrates the difference between two different alloys. This infor- mation can be extremely important when designing and building automo- biles, planes and any other item that depends on strength. For example, in a high-speed crash the aluminum would become softer and less protective. The steel, however, would get stronger than the normal driving strength.

Gathering n and m information for various materials and applications is a great help in our fast-growing tech- nical world. MF

1-800-624-8511

��� � ���� ����� ������ ��������� ��� �� ��� ����� ��������� ����� �� ���

phdinc.com/mf917 ���� ��� ���� � ���� ������ �� ����� ���

Free catalog on demand !

Sensor Technology

SENSORS

for punching, forming & process monitoring

Vester Elektronik GmbH

www.vester.de / us

I Process Monitoring

www.metalformingmagazine.com

MetalForming/September 2017 47

X

Stress

Stress σ