Page 48 - MetalForming September 2017

P. 48

The Science of Forming By Stuart Keeler

n and m Values Are Important When Forming

40,000

30,000

20,000

10,000

n = 0.5

Ultimate tensile strength

n = 0.1

0

0 10 20 30 40 50 60

Engineering strain, %

0.3

0.2

0.1

0

0 50 100

Yield strength (Ksi)

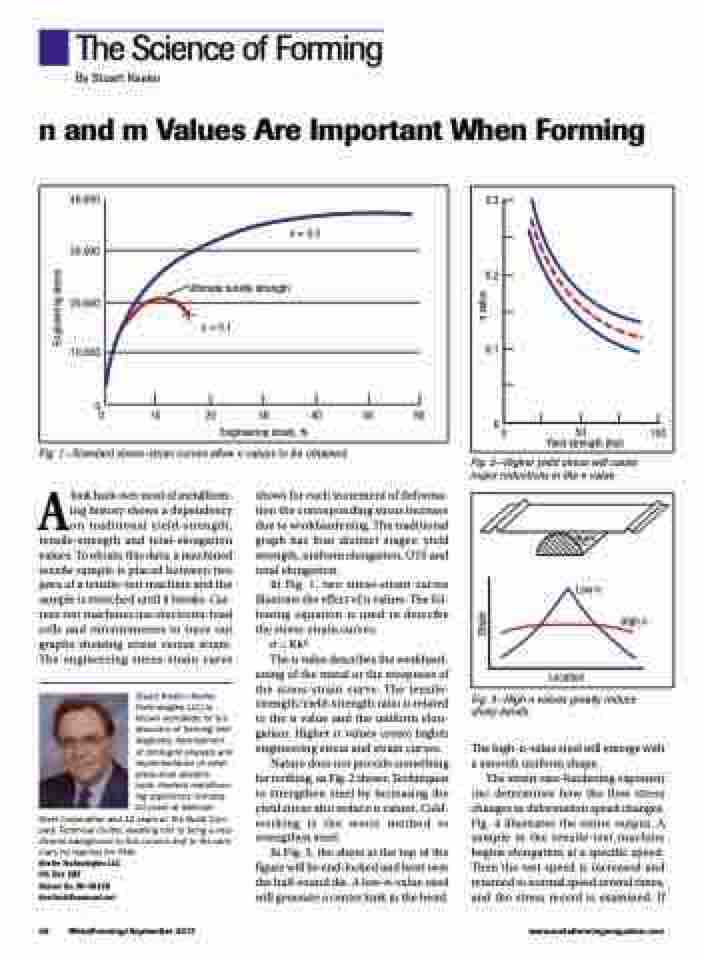

Fig. 1—Standard stress-strain curves allow n values to be obtained.

Fig. 2—Higher yield stress will cause major reductions in the n value.

Alook back over most of metalform- ing history shows a dependency on traditional yield-strength, tensile-strength and total-elongation values. To obtain this data, a machined tensile sample is placed between two jaws of a tensile-test machine and the sample is stretched until it breaks. Cur- rent test machines use electronic load cells and extensometers to trace out graphs showing stress versus strain. The engineering stress-strain curve

Stuart Keeler (Keeler Technologies LLC) is known worldwide for his discovery of forming limit diagrams, development of circle-grid analysis and implementation of other press-shop analysis tools. Keeler’s metalform- ing experience includes 24 years at National

Steel Corporation and 12 years at The Budd Com- pany Technical Center, enabling him to bring a very diverse background to this column and to the sem- inars he teaches for PMA.

Keeler Technologies LLC P.O. Box 283

Grosse Ile, MI 48138 keeltech@comcast.net

shows for each increment of deforma- tion the corresponding stress increase due to workhardening. The traditional graph has four distinct stages: yield strength, uniform elongation, UTS and total elongation.

In Fig. 1, two stress-strain curves illustrate the effect of n values. The fol- lowing equation is used to describe the stress-strain curves:

= Kn

The n value describes the workhard- ening of the metal or the steepness of the stress-strain curve. The tensile- strength/yield-strength ratio is related to the n value and the uniform elon- gation. Higher n values create higher engineering stress and strain curves.

Nature does not provide something for nothing, as Fig. 2 shows. Techniques to strengthen steel by increasing the yield stress also reduce n values. Cold- working is the worst method to strengthen steel.

In Fig. 3, the sheet at the top of the figure will be end-locked and bent over the half-round die. A low-n-value steel will generate a center kink in the bend.

Fig. 3—High n values greatly reduce sharp bends.

The high-n-value steel will emerge with a smooth uniform shape.

The strain-rate-hardening exponent (m) determines how the flow stress changes as deformation speed changes. Fig. 4 illustrates the entire output. A sample in the tensile-test machine begins elongation at a specific speed. Then the test speed is increased and returned to normal speed several times, and the stress record is examined. If

Low n

High n

Location

46 MetalForming/September 2017

www.metalformingmagazine.com

Strain n value

Engineering stress